If you are looking for a strong, abrasion-resistant fabric for backpacks, military gear, motorcycle jackets, or safety workwear, you have probably seen the term “Cordura fabric” many times.

In this guide, we’ll explain in simple language:

- What Cordura fabric is

- How Cordura-type fabrics are made

- The difference between 500D / 1000D Cordura nylon

- Cordura vs ordinary nylon & polyester

- Typical applications (bags, tactical, outdoor, workwear)

- How to choose the right Cordura-type fabric for your project

- Why do many buyers work directly with Chinese Cordura-type fabric suppliers

Note: CORDURA® is a registered trademark of INVISTA. In this article, we use “Cordura fabric” as a common industry term for high-tenacity nylon fabrics similar in performance to original CORDURA® fabrics.

1. What Is Cordura Fabric?

Cordura fabric usually refers to a high-tenacity nylon fabric, most often Nylon 6, and Nylon 6.6, woven in Oxford, canvas, or twill constructions and finished with PU / PVC / TPU / other coatings for extra performance.

Key features:

- Very high abrasion resistance

- High tear and tensile strength

- Good resistance to tearing at seams and stitching

- Durable color fastness

- Can be made water-repellent, waterproof, flame-retardant, IRR, oil-repellent, etc.

Because of these properties, Cordura-type fabrics are widely used in:

- Military & tactical gear

- Outdoor backpacks & hiking bags

- Motorcycle jackets & riding pants

- Safety workwear, tool bags & PPE

- Luggage, travel bags & camera bags

If you need a fabric that can survive heavy daily use, rough surfaces, and bad weather, Cordura-type nylon is one of the best choices.

2. How Is Cordura-Type Nylon Fabric Made?

A typical high-tenacity Cordura-type fabric goes through several steps:

2.1 High-Tenacity Nylon Yarn

- Usually Nylon 6 or Nylon 6.6

- Denier range: 330D, 500D, 650D, 1000D

- High tenacity (high breaking strength) yarn from reliable spinning mills

The denier (D) number shows the thickness of the yarn:

- The higher the denier, the thicker & stronger the fabric (and also heavier & stiffer).

2.2 Weaving

The yarn is woven on water-jet looms, air-jet looms, or rapier looms into different constructions:

- Plain / Oxford weave – common for backpacks, bags, outdoor gear

- Twill weave – slightly softer hand-feel, good for garments

- Canvas weave – higher density, heavy-duty applications

2.3 Dyeing & Finishing

Greige fabric (undyed) is sent to the dye house:

- Piece dyeing (solid colors like black, coyote, ranger green, navy)

- Solution-dyed yarn (for better color fastness and UV resistance)

- Camouflage printing for tactical and hunting gear

Finishing options:

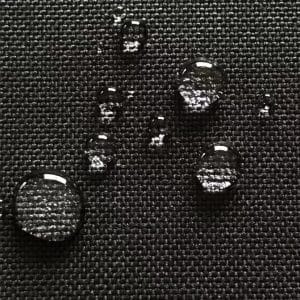

- Durable Water Repellent (DWR) finish

- PU coating (1–3 layers) for waterproof & higher stiffness

- PVC / TPU coating or lamination for 100% waterproof and high hydrostatic head

- Special finishes such as flame retardant, IRR, anti-UV, oil-repellent, easy-clean, etc.

3. 500D vs 1000D Cordura Fabric – What Is the Difference?

Many buyers are not sure whether to choose 500D or 1000D Cordura fabric. Here is a simple comparison:

3.1 500D Cordura-Type Nylon

- Medium weight, good balance of strength and flexibility

- Commonly used for:

- Day backpacks

- Tactical vests

- Lightweight plate carriers

- Motorcycle jackets

- Outdoor bags, EDC pouches

Advantages:

- Lighter than 1000D (better comfort for garments)

- Easier to sew, more flexible

- Good for products where weight is important, but you still need high durability

3.2 1000D Cordura-Type Nylon

- Heavy-duty fabric with very high abrasion resistance

- Commonly used for:

- Military rucksacks

- Heavy tool bags

- Drag bags, tactical gear

- Protective covers and cases

Advantages:

- Maximum durability and strength

- Very high resistance to tearing and surface wear

- Ideal for extreme use and heavy loads

Simple rule:

- If your product is mainly bags, MOLLE pouches, or lightweight tactical gear, choose 500D.

- If you need maximum durability for heavy bags, equipment covers, or load-bearing gear, choose 1000D.

If you are not sure, you can ask us for both 500D and 1000D samples and compare the hand-feel and weight.

4. Cordura Fabric vs Ordinary Nylon & Polyester

When sourcing fabric, you may ask:

“Why should I pay more for Cordura-type nylon instead of normal nylon or polyester?”

4.1 Cordura-Type Nylon vs Normal Nylon

- Yarn quality: Cordura-type uses high-tenacity yarn; normal nylon can be standard strength.

- Abrasion resistance: Cordura-type survives many more cycles in abrasion tests.

- Consistency: Warp and weft strength, tear strength, and coating adhesion are more stable when using good raw materials and controlled processing.

Result:

If your bags or gear will be used outdoors, on concrete, rocks, construction sites, or in the military, Cordura-type nylon fabric usually lasts much longer.

4.2 Cordura-Type Nylon vs Polyester Oxford

Polyester Oxford (e.g., 300D / 600D polyester) is cheaper and still widely used. However:

Polyester Oxford advantages:

- Lower price

- Good color fastness in light (UV)

- Suitable for daily bags, promotion bags, and simple backpacks

Cordura-type nylon advantages:

- Higher abrasion resistance

- Higher tear and tensile strength

- Better durability under heavy loads and rough surfaces

- More premium feeling for tactical & outdoor brands

So if you’re producing entry-level or promotion bags, polyester Oxford is ok.

But for medium-high-end tactical, outdoor, and workwear brands, Cordura-type nylon is normally the better choice.

5. Common Applications of Cordura-Type Fabric

Cordura-type fabrics are used in many industries. Here are some typical applications:

5.1 Backpacks & Outdoor Bags

- Hiking backpacks

- Tactical backpacks

- Laptop bags

- Hunting bags

- Camera bags

Why choose Cordura-type fabric:

- Strong enough for heavy loading

- Good resistance to abrasion from rocks, trees, car trunks, and airport belts

- Can be made water-repellent or waterproof

5.2 Military & Tactical Gear

- Plate carriers, vests

- Chest rigs, MOLLE pouches

- Magazine pouches, radio pouches

- Drag bags, rifle cases

Requirements:

- High strength and abrasion resistance

- Stable colors (coyote, ranger green, black, multicam-style camouflage)

- IRR (Infra-Red Reduction) for some military projects

5.3 Workwear & PPE

- Tool bags and tool belts

- Knee reinforcement on work pants

- Elbow reinforcement on jackets

- Safety harness sleeves

Cordura-type fabric provides extra reinforcement in areas that easily wear out.

5.4 Motorcycle & Protective Garments

- Motorcycle jackets and pants

- Reinforcement panels on shoulders, elbows, and knees

- Protective outer shells combined with inner padding

For this use, many buyers choose 500D or 650D Cordura-type fabrics with PU coating and DWR.

6. How to Choose the Right Cordura-Type Fabric

When you send an inquiry to a fabric supplier, try to prepare the following information. It will help you get faster & more accurate quotations.

6.1 Denier & Construction

- 330D / 500D / 650D / 1000D

- Oxford, twill, or ripstop

- Single layer or double layer

If you are not sure, simply tell us your final application (e.g., tactical backpack, tool bag, motorcycle jacket), and we can recommend typical constructions that other customers are using.

6.2 Coating & Functional Requirements

- No coating + DWR only – breathable, lighter

- 1–2 layers PU coating – water resistance + more body

- Heavy PU, PVC, or TPU – 100% waterproof, very strong

- Optional:

- FR (flame retardant)

- IRR for military

- Anti-UV for outdoor

- Oil & stain-repellent finishes

The more functions you add, the higher the cost – but also the higher the performance and brand positioning.

6.3 Color & Printing

- Solid colors (we can match Pantone or your physical swatch)

- Camouflage printing (woodland, digital camo, multicam-style, custom patterns)

- Small MOQ digital printing for new designs or small collections

6.4 Test Standards

If your customer requires specific standards, please tell the supplier clearly:

- Tensile strength, tear strength

- Abrasion (Martindale or Taber)

- Hydrostatic head (waterproof level)

- Color fastness to washing, rubbing, and light

- Flame-retardant standards, if needed

The more details you provide, the easier it is for the mill to select the right base fabric and finishing process.

7. Working With a Cordura-Type Fabric Supplier in China

If you are a brand, wholesaler, or factory buying fabric for bags, gear, or garments, working directly with a professional Cordura-type fabric supplier in China brings several advantages:

7.1 Competitive Price

- Direct mill or fabric converter prices

- One-stop solution from weaving to dyeing, coating, and lamination

- More flexible on MOQ and color options than large international brands

7.2 Customization for Your Brand

You can ask for:

- Special colors or custom camouflage

- Your target weight and hand-feel

- A specific combination like:

- 500D high-tenacity nylon, Oxford weave, PU 2-3 coating, DWR, 58/60 ” width, 220–260gsm

With clear requirements, the factory can design a fabric that best fits your product positioning and budget.

7.3 Sample Support

A good supplier will:

- Provide free A4 swatches or small sample rolls

- Help you test and adjust the construction

- Support your new product development with stable quality

8. How to Send an Effective Cordura Fabric Inquiry

To get a fast and accurate offer, you can send an email like this:

Subject: Inquiry – 500D & 1000D Cordura-Type Nylon Fabric for Backpacks

Hello,

We are looking for 500D and 1000D Cordura-type nylon fabric for our backpack and tactical gear production.

Basic requirements:

- Material: High tenacity nylon (Cordura-type)

- Denier: 500D and 1000D

- Weave: Oxford

- Finish: DWR + PU coating (2–3 times), waterproof

- Width: 58/60″”

- Colors: Black, Coyote, Ranger Green

- Application: Outdoor backpacks & tactical gear

- Please advise: weight (gsm), test data (tensile, tear, abrasion, water column), and MOQ.

Kindly send us your price, minimum order quantity, lead time, and available sample colors.

Best regards,

[Your Name]

[Your Company]

You can copy this template, adjust the details, and send it directly to us.

9. Ready to Source Cordura-Type Nylon Fabric?

If you are planning a new bag, tactical gear, workwear, or motorcycle garment collection, choosing the right Cordura-type fabric at the beginning will save you a lot of time and cost later.

We can support you with:

- 330D / 420D / 500D / 600D / 1000D / 1680D high-tenacity nylon fabrics

- PU / PVC / TPU coating, lamination, DWR, FR, IRR, and other finishes

- Solid colors and custom camouflage printing

- Sample development and stable bulk production

Send us your fabric specification or sample photos today – we will recommend suitable constructions, provide free swatches, and quote you a competitive price for your market.

You can contact us via:

- Email: [email protected]

- WhatsApp / WeChat: 008615051486055

- Contact form on our website

Tell us what products you are making and what performance you need, and we will help you choose the most suitable Cordura-type fabric solution for your project.