When buyers look for waterproof Cordura nylon for backpacks, motorcycle bags, or riding gear, they often see two key constructions on the TDS:

- PU-coated Cordura nylon

- TPU laminated Cordura nylon

Both can be called “waterproof”, but their hydrostatic head, durability, and real-world performance can be very different. In this article, we’ll compare PU coating vs TPU lamination on Cordura nylon, especially for bags and motorcycle gear, and help your customers understand what they’re really paying for.

1. PU Coated vs TPU Laminated: What’s the Difference?

PU Coated Cordura Nylon

PU (polyurethane) coating is usually applied to the back side of the fabric in liquid form, then dried and cured. Typical construction:

- Face side: Cordura nylon (e.g., 500D, 1000D, etc.)

- Back side: 1–2 layers of PU coating, sometimes “milky” or clear

Key features:

- Can reach basic to mid-level waterproof ratings (often around 1,000–5,000 mm water column, depending on coating weight and quality).

- Adds body and stiffness, but normally remains reasonably flexible.

- Widely used in backpacks, tactical gear, and standard outdoor bags.

- Cost-effective for mass production.

TPU Laminated Cordura Nylon

TPU (thermoplastic polyurethane) lamination uses a solid TPU film bonded to the fabric with heat and pressure (and sometimes adhesive). Typical construction:

- Face side: Cordura nylon

- Back side: Continuous TPU film (often 0.02–0.05 mm or more)

Key features:

- Creates a continuous waterproof barrier that can reach very high hydrostatic head (often 10,000–20,000 mm or more, depending on film thickness and bonding).

- Very reliable for long-term waterproof performance when properly laminated and seam-taped.

- Favored in premium motorcycle gear, technical dry bags, and heavy-duty waterproof packs.

- Higher cost and slightly heavier than a single PU coating.

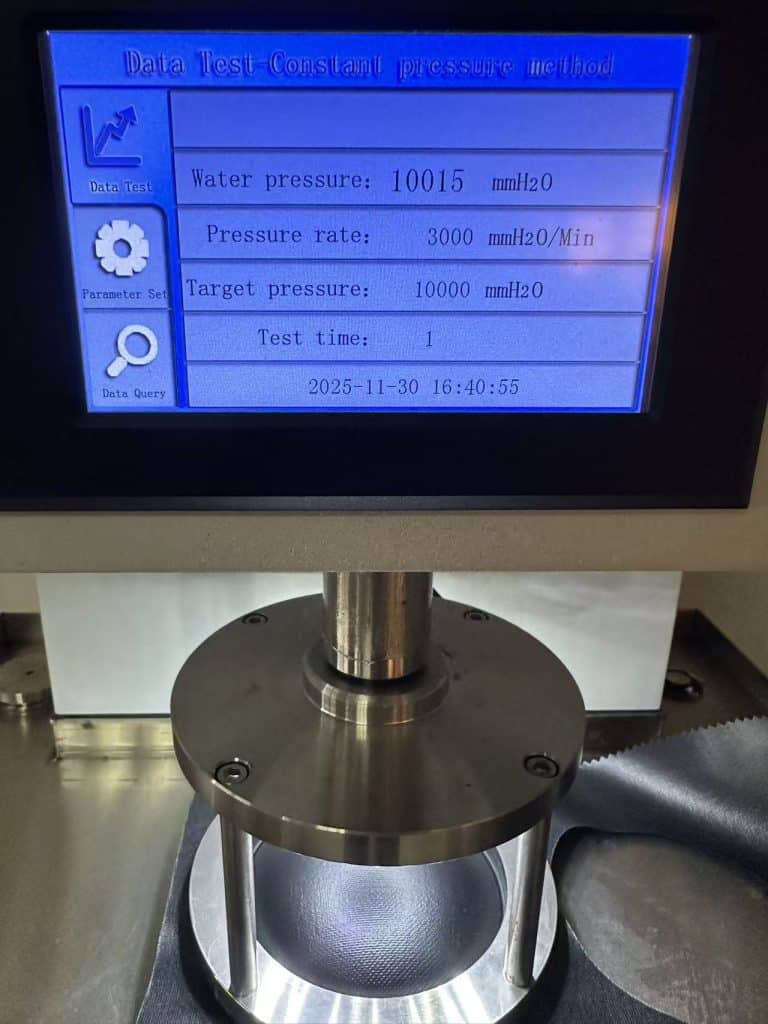

2. How Waterproofness Is Measured: Hydrostatic Head

To compare PU-coated vs TPU laminated Cordura, you should educate your buyers about hydrostatic head.

- Hydrostatic head is usually expressed as mm H₂O.

- It means how high a column of water the fabric can resist before water penetrates through.

- For example:

- 1,500 mm = basic waterproof for light rain.

- 5,000 mm = solid waterproof protection for most outdoor bags.

- 10,000–20,000 mm = high waterproof performance used in ski/snow gear, technical shells, and motorcycle gear in heavy rain at speed.

3. PU Coated Cordura: Pros & Cons for Bags and Motorcycle Gear

Advantages of PU Coated Cordura

- Cost-Effective Waterproof Solution

- PU coating is relatively economical. For daypacks, school bags, urban backpacks, or casual motorcycle tail bags, a good PU coating often provides enough waterproof protection in light to moderate rain.

- Good Balance of Flexibility and Stiffness

- A single or double PU coat adds some body without making the fabric too stiff. This is great for:

- Back panels, pockets, and flaps on bags

- Internal lining of motorcycle bags where a high hydrostatic head is not critical

- Easier to Sew and Handle

- Compared to thick TPU film, PU-coated fabrics often feed more smoothly through standard industrial sewing machines and have less risk of needle heating or film sticking.

- Lighter Than Heavy TPU Laminates

- At similar levels of waterproofness, a simple PU coat can be lighter than a thick TPU film, which is useful for EDC-style bags and backpacks.

Limitations of PU Coated Cordura

- Hydrostatic Head Is Limited

- Even with a good PU coating, typical water column values are often in the 1,000–5,000 mm range (depending on your TDS). For heavy, long-term rain at highway speed, water pressure can be much higher, especially on horizontal surfaces and seams.

- Hydrolysis and Aging

- PU can be sensitive to hydrolysis (breakdown under moisture + heat + time), leading to:

- Peeling or sticky back side

- Loss of waterproof performance

- Unpleasant odor in old gear

- Using good-quality PU systems and proper storage helps, but TPU films generally have better long-term stability.

- Requires Good Construction to Stay Waterproof

- A PU-coated fabric by itself is only part of the system. You also need:

- Proper seam construction

- Possibly seam tape on critical seams

- Good patterns to avoid water pooling

For motorcycle clothing, many brands use PU coatings as a mid-range solution or as a secondary layer, but premium “guaranteed to keep you dry” products often rely on laminates.

4. TPU Laminated Cordura: Pros & Cons for Technical Waterproof Gear

Advantages of TPU Laminated Cordura

- Very High Hydrostatic Head

- A continuous TPU film generally delivers a much higher water column than a PU coating at similar fabric weights. For demanding applications, it’s easier to reach 10,000–20,000 mm H₂O or more with TPU laminates.

- This is ideal for:

- Dry bags and waterproof duffel bags

- Motorcycle panniers and tail bags that face heavy rain and road spray

- Waterproof jackets and pants for long-distance riding

- Excellent Long-Term Waterproof Stability

- Quality TPU films have strong resistance to hydrolysis compared with many standard PU coatings. That means:

- Less chance of peeling or stickiness over time

- More consistent waterproof performance even after years of use

- Better Seam Taping Reliability

- TPU films are very compatible with heat-activated seam tapes and RF welding. For high-end motorcycle gear, seamless or welded construction can eliminate stitch holes and dramatically improve performance.

- Smooth, Clean Back Side

- The film gives the fabric a smooth, non-fibrous back. This is useful inside bags (easy to wipe clean) or inside garments as a barrier layer.

Limitations of TPU Laminated Cordura

- Higher Cost

- TPU film and lamination processes are more expensive. This directly raises the cost of your fabric and finished products.

- Heavier and Stiffer at High Film Thickness

- Thicker TPU films used for very high hydrostatic head can make the fabric stiffer and heavier, especially at low temperatures.

- More Sensitive to Process Conditions

- Lamination and seam-taping require strict control of temperature, pressure, and speed. Poor lamination can cause delamination, bubbles, or film damage.

For premium motorcycle gear and technical bags, TPU lamination is often the preferred choice when the buyer is serious about waterproof performance and willing to pay for it.

5. Waterproof Performance on Bags: PU vs TPU

For backpacks, duffel bags, and everyday carry, the key question is:

“How waterproof do we really need to be?”

When PU Coated Cordura Is Enough

PU-coated Cordura is usually sufficient if:

- The bag is used mostly in urban or commuting environments.

- Exposure to rain is occasional and moderate.

- The customer expects “rain-resistant” or “weather-resistant” but not a dry-bag-level guarantee.

Typical applications:

- Laptop backpacks and office bags

- Daypacks and school bags

- Casual motorcycle tail bags used with an extra rain cover

When TPU Laminated Cordura Is a Better Choice

TPU-laminated Cordura becomes necessary when:

- The bag must remain waterproof in heavy rain for hours, e.g., on a motorcycle at 80–120 km/h.

- The product is sold as a “dry bag” or “100% waterproof motorcycle luggage”.

- The buyer cares about IP ratings or demands a high water column in tenders.

Typical applications:

- Motorcycle panniers, tail bags, and tank bags are marketed as waterproof

- Roll-top dry bags and river duffels

- Technical expedition packs

On your site, you can present a side-by-side hydrostatic head chart and clearly label:

- PU coated: “Rain-resistant / waterproof for everyday use.”

- TPU laminated: “Heavy-duty waterproof for long, intense rain and wet conditions.”

6. Waterproof Performance in Motorcycle Gear: Jackets and Pants

For motorcycle jackets and pants, things become more demanding:

- The rider faces driving rain at speed, which increases dynamic water pressure on the fabric.

- Water can pool and push at zippers, crotch seams, shoulders, and knees.

- The gear must continue to perform after repeated flexing, vibration, and UV exposure.

Common Constructions

- Outer shell with PU-coated liner

- Outer Cordura fabric repels most water.

- Inner PU-coated liner provides extra protection.

- Often described as “waterproof liner” systems.

- 2-layer or 3-layer TPU-laminated Cordura

- Waterproof membrane laminated directly to the face fabric (and possibly to a backing).

- Offers better long-term waterproof performance and more stable hydrostatic head.

For a premium touring or adventure jacket, TPU laminates usually offer more confidence to riders who cross long distances in heavy rain.

7. Conclusion: Which Is Better – PU Coated or TPU Laminated Cordura?

There is no single winner, but there is a better fit for each product:

- PU Coated Cordura Nylon

- Best for: everyday backpacks, urban bags, standard motorcycle bags, and mid-range gear.

- Advantages: cost-effective, flexible, lighter, adequate waterproof performance for normal rain.

- Limitation: Hydrostatic head and long-term stability are lower than those of TPU laminates.

- TPU Laminated Cordura Nylon

- Best for: dry bags, waterproof motorcycle luggage, technical jackets, and pants that must stay dry in heavy rain.

- Advantages: very high hydrostatic head, strong long-term waterproof stability, excellent seam taping.

- Limitation: Higher cost, slightly heavier, and stiffer.

8. FAQ: PU Coated vs TPU Laminated Cordura Nylon

Q1: Is TPU laminated Cordura always more waterproof than PU-coated Cordura?

In most cases, yes. A proper TPU film lamination can reach much higher hydrostatic head than a standard PU coating at similar fabric weights. However, the actual performance depends on the film thickness, lamination quality, and your TDS, so always refer to tested values.

Q2: Does PU-coated Cordura count as “waterproof” or just “water-resistant”?

It depends on your hydrostatic head result and marketing positioning.

- Around 1,000–2,000 mm is often sold as “water-resistant” or “light waterproof”.

- Above 3,000–5,000 mm is often considered waterproof for regular use.

- But for motorcycle gear in heavy rain, some brands prefer higher numbers, especially for critical panels.

Q3: Which one is better for a commuting backpack?

For daily commuting, laptop backpacks, and urban EDC bags, PU-coated Cordura is usually enough. It gives a good balance of weight, cost, and protection. TPU laminates are more suitable when you want to promote the bag as “fully waterproof” or “dry bag level”.

Q4: Which one should I choose for motorcycle saddle bags and panniers?

If the bags are exposed to long, heavy rain at speed and customers expect the contents to stay dry without additional covers, TPU laminated Cordura is the safer choice. For more casual or budget-oriented bags, PU-coated Cordura may be acceptable with a separate rain cover.

Q5: How do PU and TPU compare in long-term durability?

High-quality TPU films usually show better resistance to hydrolysis and sticking over time compared with many standard PU coatings. PU-coated fabrics can last many years, but they are more sensitive to high humidity, heat, and poor storage. Good formulation and good storage conditions are key.

Q6: Can you seam-tape PU-coated fabrics as well?

Yes, PU seam tapes exist and are widely used. However, TPU laminated fabrics often provide stronger bonding and more consistent seam sealing, especially when using TPU-based seam tapes and welded constructions.

Q7: Is TPU laminated Cordura breathable?

Standard solid TPU films are usually not very breathable. If your customer needs breathable waterproof garments, you may need a special microporous or hydrophilic membrane system (also often based on PU or other polymers) rather than a simple solid TPU film. For bags and luggage, breathability is usually not a priority.

Q8: Can I offer both PU and TPU options to the same customer?

Absolutely. A good strategy is:

- Offer PU-coated Cordura as the cost-effective solution.

- Offer TPU laminated Cordura as the premium, high-waterproof solution.

9.Request Latest Price & Free Fabric Samples

If you are developing waterproof bags, motorcycle luggage or riding gear and need to compare PU coated vs TPU laminated Cordura-type nylon on real cost and performance, feel free to contact us for:

Latest FOB price for your target specification

Hydrostatic head test data (SGS / CNAS)

Small yardage & swatches for your sampling and approval

Contact Us for a Quote:

Company: LEAN TEXTILE CO., LIMITED

Website: www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055

Send us your denier, coating/lamination requirement, color and target usage (bag / pannier / jacket / pants) and we will recommend a suitable construction and quote you accordingly.