Modern military and law-enforcement gear is built around one practical idea: carry more, move faster, and keep equipment reliable under abrasion, mud, rain, and repeated handling. For textile buyers and gear designers, that usually means choosing a fabric that balances durability, weight, flexibility, and sewability—not simply the “heaviest” option.

That’s exactly where Nylon 500D Cordura-type fabric performs well. In many tactical products, 500D is the “sweet spot”: strong enough for demanding use, but lighter and more manageable than heavier deniers—especially when the product includes multiple layers, webbing, foam, and hardware. Your site positions 500D as a medium-weight choice for backpacks, tactical pouches, and performance bags, and highlights that it’s widely used because it balances strength, weight, and flexibility.

Note on naming: CORDURA is a registered trademark of INVISTA. In the market, “Cordura-type” is often used to describe similar high-tenacity nylon constructions.

1) What “500D” Really Means for Military Gear Buyers

Denier (D) is a yarn-size measure, and in tactical gear it’s often treated as shorthand for a whole performance package: abrasion resistance, tear strength, fabric body, and product weight.

In real gear builds, 500D is frequently selected when:

- The product will be worn for long periods (plate carrier accessories, chest rigs, belts, pouches)

- The user needs mobility (patrol packs, assault packs, small load-bearing items)

- designers want strong fabric without excessive stiffness or weight

Your 500D product page frames 500D as medium-weight, engineered for an ideal balance of strength, weight, and flexibility.

2) Typical Military & Tactical Use Cases for Nylon 500D

This section focuses on textile applications for carrying systems, protective equipment covers, and field gear—not weapons.

A) Modular load carriage (MOLLE / PALS pouches and accessories)

500D is commonly used for:

- utility pouches, admin pouches, dump pouches

- magazine pouches and small load-bearing equipment

- plate carrier accessories and chest rig components

Why it works:

- enough abrasion resistance for frequent contact and rubbing

- easier handling in sewing compared with thicker/heavier builds

- better comfort/fit when worn close to the body

B) Backpacks and patrol/assault packs

For packs, fabric choice is rarely “one material everywhere.” A common approach is:

- 500D for main panels (weight savings + comfort)

- reinforcement strategies for high-wear zones (corners, bottoms, strap anchors)

C) Tactical apparel reinforcement and motorcycle/protective wear overlap

Military procurement and tactical brands often share supply chains with protective gear markets. 500D is used for:

- reinforcement panels (knees, elbows, shoulders)

- rugged outer surfaces where abrasion is expected

D) Field equipment bags, tool bags, covers, and organizers

Support gear matters: medical bags, comms/optics carry bags, and rugged organizers. 500D is widely specified when the item must remain portable but durable.

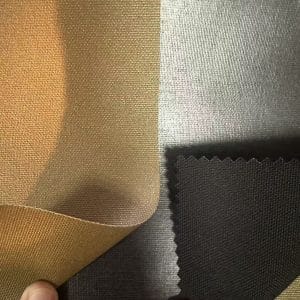

3) Plain Weave vs Ripstop: Choosing Structure for Real Field Conditions

On your 500D page, buyers can choose Plain / Ripstop.

A practical way to decide:

- Plain weave 500D: clean appearance, stable body, great for packs and pouches where the panel is already supported by foam and webbing

- Ripstop 500D: the reinforcement grid can help prevent a small puncture/tear from spreading—useful for outerwear panels, softer structures, or any product likely to snag on brush/metal edges

4) Nylon 6 vs Nylon 66: What Buyers Usually Care About

You offer high-tenacity Nylon 6 or Nylon 66 options for 500D.

From a sourcing standpoint:

- Nylon 6: widely available, cost-effective, strong enough for many tactical products

- Nylon 66: often specified when buyers want higher heat resistance and slightly higher tensile strength for demanding programs

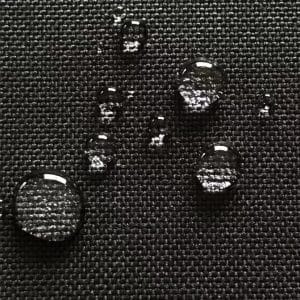

5) Coating / Lamination: The Real “Performance Lever” in Military Gear

In tactical programs, the denier alone doesn’t decide the final performance. The backside system—PU coating or TPU lamination—drives:

- waterproof level (hydrostatic head)

- long-term aging and hydrolysis risk

- fabric stiffness and sewing behavior

PU coated 500D (practical everyday waterproof)

Your page indicates:

- PU waterproof level: about 500–3000 mm

- common positioning: everyday backpacks, tactical pouches, general outdoor bags, reinforcement panels.

PU coatings are a strong default when:

- The gear needs water resistance, not “dry bag” performance

- Buyers care about cost and smooth production

TPU laminated 500D (higher waterproof and long-term reliability)

- TPU waterproof level: about 5000–10,000 mm

- positioning: motorcycle gear, outdoor packs, heavy rain conditions

6) IRR and Camouflage Programs: What to Specify

Military and law-enforcement textile programs sometimes add an IRR (infrared reflectance/signature management) requirement, especially for camouflage systems.

On your 500D product page, you present a Multicam-style 500D option with IRR finishing, described as helping reduce infrared signature for professional military and law enforcement use.

7) What a Good 500D “TDS Conversation” Looks Like

If you want faster, cleaner inquiries from military/tactical buyers, encourage them to send these fields:

- Yarn type: Nylon 6 or Nylon 66

- Weave: plain or ripstop.

- Width: 57/58″ or 58/60″

- Target weight: your typical range is 200–270 gsm, customizable

- Backside system:

- PU 500–3000 mm, or

- TPU 5000–10,000 mm

- Finishing: DWR / IRR / UV / printed / calendared, etc.

- Color: Pantone or physical sample

- MOQ & roll length: you list MOQ 500 m per color and 50–100 m per roll (as requested).

When you communicate this way, the buyer feels you understand procurement realities—and you reduce the “back-and-forth” that kills conversion.

8) Why 500D Keeps Winning in Military & Tactical Programs

To summarize the “why,” Nylon 500D Cordura-type fabric remains a go-to choice because it delivers:

- strong mechanical performance (your page provides typical tensile and tear values and emphasizes abrasion resistance)

- functional flexibility (PU vs TPU vs optional systems)

- program-level options like IRR and FR (on request)

- practical manufacturability for pouches, packs, and load-bearing accessories that must be sewn efficiently at scale

For many product categories, 500D is the most economical way to hit the performance target without overbuilding the product.

FAQ

Q1: Is 500D Cordura strong enough for military backpacks and MOLLE pouches?

Yes—500D is widely used for tactical backpacks, MOLLE pouches, and small load-bearing equipment because it balances durability and weight.

Q2: When should I choose 1000D instead of 500D?

Choose 1000D when the product needs maximum stiffness and abrasion resistance (large rucksacks, heavy-duty packs, high-abuse panels). Your site positions 1000D/1050D as heavy-duty for plate carriers and military packs.

Q3: Plain weave or ripstop—what’s better for tactical gear?

Plain weave is a classic choice for packs and pouches; ripstop helps stop small tears from spreading and is useful for technical panels and outerwear.

Q4: PU coated vs TPU laminated—how do I pick?

PU is usually the cost-effective choice for everyday water resistance (about 500–3000 mm on your 500D page). TPU is for higher waterproof requirements (about 5000–10,000 mm) and can be paired with seam taping for waterproof products.

Q5: What does “hydrostatic head” mean?

It’s the waterproofness metric expressed as mm H₂O—how much water pressure a fabric resists before leaking. Your article gives reference points like 5,000 mm for solid protection and 10,000–20,000 mm for high waterproof performance.

Q6: Can you supply Nylon 6 and Nylon 66 in 500D?

Yes—your 500D page offers both, and notes Nylon 66 can be preferred for some tactical/military programs due to higher heat resistance and slightly better tensile strength.

Q7: Do you offer IRR finishing for camouflage tactical fabric?

Yes—your product page lists a Multicam-style 500D with IRR finishing described for military/law-enforcement use. Final requirements should match the buyer’s spec and testing method.

Q8: What’s the typical MOQ for 500D Cordura fabrics?

Your page lists MOQ as 500 m per color (depending on item and color).

CALL TO ACTION

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: https://www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055