Nylon 330D Cordura Fabric: How to Choose the Best Build for Lightweight Backpacks

If you’re developing a modern daypack, commuter backpack, camera insert, or lightweight outdoor bag, material choice is often the difference between a product that feels premium and lasts—and one that pills, tears, or wets out too quickly.

That’s where Nylon 330D Cordura-type fabric shines. It’s designed for brands that want a lighter, softer handfeel than 500D while still keeping dependable abrasion and tear performance for daily carry and mid-duty use.

In this guide, you’ll learn exactly how to choose the right 330D build (yarn type, weave, coating, and finishes), what specs to request from your supplier, and how to avoid the most common sourcing mistakes.

Looking for the product overview and TDS range first?

Check our core page here:Nylon 330D Cordura Fabric; (then come back for the practical decision guide).

1) What “330D” really means (and what it does not mean)

Denier (D) is a unit that describes the linear density of the yarn. In simple terms: higher denier yarns are thicker and generally produce heavier, tougher fabrics. But denier alone doesn’t guarantee durability.

For a backpack fabric, real performance depends on:

Yarn quality (standard vs high-tenacity Nylon 6 / Nylon 66)

Weave + density (plain vs ripstop; ends/picks)

Coating/lamination system (PU vs TPU; layer count; adhesion)

Finishing package (DWR, calendaring, IRR, UV, etc.)

So treat “330D” as your starting point—not your full spec.

2) Why choose 330D instead of 500D or 1000D?

330D is a preferred choice when your product must feel lighter, less stiff, and more comfortable, while still being durable enough for everyday abrasion and regular outdoor use. LEAN TEXTILE

Choose 330D when your product is:

Daypacks & commuter backpacks

Travel organizers, laptop sleeves

Camera inserts, packing systems

Light trekking bags and hybrid gear where weight matters

Choose 500D/1000D when:

You expect heavy load-bearing, dragging, rough surfaces, or sustained hard use

You’re building military rucksacks, heavy tactical packs, tool bags, or extreme abrasion zones

A simple product-design rule:

330D = lightweight performance

500D = all-around “sweet spot”

1000D = maximum durability (with higher weight and stiffness)

3) Nylon 6 vs Nylon 66 for 330D: which should you pick?

On the 330D platform, many buyers ask: “Do I really need Nylon 66?”

Nylon 6 (high tenacity): strong, cost-efficient, widely used for outdoor and bag applications.

Nylon 66 (high tenacity): often chosen for higher tensile performance and heat resistance, and for more premium or tactical accessory lines.

If your brand sells “ultralight-but-tough,” Nylon 66 is a strong positioning choice.

4) Plain vs Ripstop: what changes in real-world products?

Your weave affects handfeel, tear behavior, and surface aesthetics.

Plain weave (common choice)

Balanced abrasion resistance

Clean, classic backpack look

Great for panels, gussets, and general bag bodies

Ripstop (when tear control matters)

Reinforcement grid helps resist tear propagation

Often preferred for lighter designs that still want “confidence” against snags

Great for travel organizers, lightweight outdoor packs, and some tactical accessories

Practical recommendation:

If your design uses thin foam + lining and you want a premium look, start with plain weave. If your customer expects rough handling, try ripstop.

5) The most important decision: PU coating vs TPU lamination

Your waterproof performance and “premium feel” depend heavily on the backing system.

From our 330D range:

PU coating typically targets about 300–2000 mm hydrostatic head (depending on layers and structure).

TPU lamination typically targets about 3000–8000+ mm (structure-dependent) with a cleaner handfeel.

PU Coated 330D (1–3 layers)

Best for:

Everyday backpacks

Travel bags and organizers

Products where you want cost-effective water resistance

Watch-outs:

PU hydrolysis risk exists over time; high-quality systems improve durability (ask for hydrolysis expectation and storage guidance).

TPU Laminated 330D

Best for:

Rain-exposed compartments

Lightweight outdoor packs that need higher waterproofing

Premium “clean backing” look and feel

Watch-outs:

Higher cost, and specs must be clear (target mm, backing fabric, lamination structure)

6) A quick spec table you can copy into your inquiry

Below is a buyer-friendly baseline spec range (customization is normal):

| Spec Item | Typical Range / Option |

|---|---|

| Yarn | High-tenacity Nylon 6 or Nylon 66 |

| Denier | 330D |

| Weave | Plain or Ripstop |

| Width | 57/58″ or 58/60″ (1.47–1.50m) |

| Weight | 160–220 gsm (customizable) |

| Coating | PU (1–3 layers) or TPU lamination |

| Waterproof | PU: ~300–2000mm; TPU: ~3000–8000+mm |

| Finishing | DWR, soft handfeel, IRR, UV, printed, calendared (optional) |

| MOQ | ~300–500m per color (item/color dependent) |

7) What durability numbers should you request?

For bags, “durable” must be measurable. Ask your supplier for:

Tensile strength (warp/weft)

Tear strength (warp/weft)

Abrasion (Martindale cycles)

Color fastness to rubbing (dry/wet)

Dimensional stability/shrinkage

Our typical 330D mechanical reference ranges include tensile 900–1600N (warp) and abrasion 50,000–80,000 rubs, depending on final item construction.

8) Buyer checklist: avoid these 5 common sourcing mistakes

Only specifying “330D”

→ Add weight (gsm), weave, yarn type, and target waterproof level.Not clarifying the waterproof requirement

→ Define: “light rain,” “daily water resistance,” or “rain compartment waterproof.”Ignoring handfeel requirements

→ TPU often feels cleaner/premium; PU can be more economical but varies a lot.Skipping color standards

→ Use Pantone references and request lab dip approval for bulk.No pre-production sample approval

→ Always confirm bulk consistency with counter sample and shade control.

9) Recommended internal link for conversions

For full specs, coating options, MOQ, and to request samples/TDS, visit: Nylon 330D Cordura Fabric

10) FAQ (for Google/AI snippets)

Q1: Is 330D strong enough for backpacks?

Yes—330D is excellent for daypacks, commuter packs, travel bags, and many lightweight outdoor designs. For heavy load-bearing or extreme abrasion, 500D/1000D is usually better.

Q2: What waterproof level can 330D achieve?

PU coating typically targets ~300–2000mm; TPU lamination can reach ~3000–8000+mm depending on structure.

Q3: Plain or ripstop—what’s better?

Plain weave is the most universal for bag panels. Ripstop is great when you want extra tear control and a technical look.

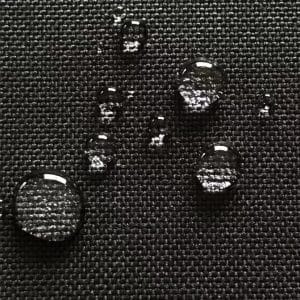

Q4: Can I request DWR on 330D?

Yes, DWR is commonly used to improve surface water beading and reduce wet-out.

Q5: What’s the usual MOQ?

MOQ is typically around 300–500m per color, depending on item and color.

Contact

If you’re sourcing 330D for backpacks or outdoor gear, we can recommend the best construction, send free swatches, and provide the TDS quickly.

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: https://www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055