When choosing the right textile for gear, apparel, or outdoor equipment, Nylon 500D Cordura Fabric stands out as a leading option. Renowned for its superior strength, abrasion resistance, and long-lasting durability, this fabric has become a staple in industries ranging from tactical gear manufacturing to high-performance outdoor apparel. In this comprehensive guide, we’ll explore everything you need to know about 500D Cordura Nylon, including its benefits, common uses, and tips on choosing and caring for it.

1. What is 500D Cordura Nylon Fabric?

500D Cordura Nylon is a high-tenacity nylon fabric originally developed by DuPont and now produced by INVISTA. The “500D” refers to its denier count—denier being a measure of fiber density and thickness. At a mid-range denier level, 500D Cordura balances weight, strength, and flexibility, making it a versatile fabric well-suited for various applications.

Key Properties and Benefits

- Exceptional Durability:

- One of the most notable features of 500D Cordura Nylon is its remarkable durability. Its tightly woven nylon fibers are engineered to resist wear and tear, prolonging the fabric’s lifespan even under demanding conditions. This makes it ideal for heavy-use products like backpacks, duffel bags, and tactical equipment.

- High Abrasion Resistance:

- Durability goes hand-in-hand with abrasion resistance. Whether dragging a backpack across rough terrain or your gear is in constant contact with abrasive surfaces, the 500D Cordura stands up to the challenge. It’s significantly more resistant to scuffing and tearing than standard nylon fabrics.

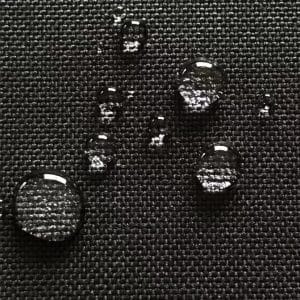

- Water and Stain Resistance:

- While not inherently waterproof, Nylon 500D Cordura Fabric can be treated with water-resistant coatings such as polyurethane (PU) or a durable water-repellent (DWR) finish. These treatments help the fabric shed moisture and resist stains, making it easier to maintain and clean.

- Lightweight Versatility:

- Although incredibly tough, 500D Cordura is lightweight compared to heavier fabrics like 1000D Cordura. This makes it perfect for gear that needs to remain portable, such as daypacks, travel bags, and lightweight tactical vests.

- Color Retention and Fade Resistance:

- Thanks to advanced dyeing techniques, 500D Cordura Nylon is known for retaining its color even after exposure to harsh sunlight, repeated washing, and extreme outdoor conditions. This means your products maintain their aesthetic appeal over time.

2. Common Applications of 500D Cordura Nylon

- Tactical and Military Gear:

- Law enforcement and military personnel rely on the strength of 500D Cordura Nylon for body armor carriers, pouches, and plate carriers. Its resilience ensures the gear can withstand strenuous missions, rough handling, and repeated use.

- Outdoor and Adventure Equipment:

- If you’re an avid hiker, climber, or camper, you’ve likely encountered 500D Cordura in backpacks, sleeping bag covers, and tent panels. Its durability and water resistance make it a top choice for equipment that faces the elements head-on.

- Travel and Luggage:

- High-quality luggage and travel accessories benefit from the ruggedness of the 500D Cordura. From suitcases and duffel bags to laptop cases, this fabric offers a balance of durability and mobility, ideal for frequent flyers and adventurers.

- Apparel and Footwear Reinforcements:

- Specific garments and footwear incorporate 500D Cordura panels in high-wear areas, such as elbows, knees, and boot uppers. This reinforcement extends product life, ensuring you can depend on your gear for years.

3. How to Choose High-Quality 500D Cordura Fabric

- Check the Source:

- Ensure you’re purchasing from reputable suppliers who guarantee the authenticity of their Cordura fabrics. Genuine 500D Cordura is produced by INVISTA or authorized mills that meet stringent quality standards.

- Look for Coatings and Finishes:

- Consider the additional features you need—such as PU coatings or DWR treatments—to enhance water and stain resistance. Always verify that the fabric meets your specific performance requirements.

- Assess Weight and Thickness:

- While 500D is a standard denier, fabrics vary slightly in weight and thickness. Request samples or consult with suppliers about the specific properties before purchasing bulk.

4. Caring for Your 500D Cordura Products

- Regular Cleaning:

- Gently brush off dirt and debris, then spot clean with a mild detergent. Avoid harsh chemicals and abrasive brushes that may damage the fibers.

- Proper Drying:

- Air-dry your products rather than using a dryer. High heat can weaken the nylon fibers and reduce the fabric’s lifespan.

- Occasional Reapplication of DWR Coatings:

- If your gear loses its water repellency over time, consider reapplying a DWR treatment. This helps maintain the fabric’s protective qualities against moisture and stains.

5. Sustainability and Future Innovations

As environmental awareness grows, many manufacturers seek sustainable alternatives and eco-friendly coatings for 500D Cordura. Recycled nylon fibers and greener dyeing processes are increasingly available, ensuring that future iterations of Cordura fabrics remain tough and eco-conscious.

6. Final Thoughts

Nylon 500D Cordura Fabric offers an exceptional blend of durability, flexibility, and resistance to the elements. Its versatile applications—tactical gear, outdoor equipment, luggage, and reinforced apparel—prove its enduring popularity. By choosing genuine 500D Cordura from reputable suppliers and maintaining it properly, you can expect your products to stand the test of time, ensuring you get the most out of every adventure.

Whether you’re a product designer, a retail brand, or a consumer searching for reliable materials, 500D Cordura Nylon remains a go-to fabric choice. Invest in quality, and you’ll enjoy the benefits of this proven textile for years to come.

7.Ready to Source 500D Cordura-Type Nylon for Your Project?

If you’re developing tactical backpacks, plate carriers, pouches, motorcycle bags or workwear and need a stable supplier of 500D Cordura-type nylon fabrics, we can support you with:

Recommended constructions and finishes (PU coated, TPU laminated, IRR, FR, etc.)

Full TDS with tensile, tear, abrasion and hydrostatic head data

SGS / CNAS test reports on request

Swatches and small yardage for sampling and prototyping

FAQ

1) What is Nylon 500D Cordura fabric?

Nylon 500D Cordura fabric generally refers to a high-durability nylon textile made with 500-denier yarns and engineered for excellent abrasion resistance, tear strength, and long service life. It’s widely used for rugged gear where strength-to-weight balance matters.

2) What does “500D” mean?

“D” stands for denier, a unit that indicates the thickness/linear density of the yarn. 500D is a mid-to-heavy specification that typically offers a strong blend of durability and manageable weight compared with lighter options like 330D or 420D.

3) How does 500D compare with 1000D Cordura?

500D is lighter, more flexible, and easier to achieve everyday comfort and packability.

1000D is tougher in extreme-duty use but heavier and stiffer.

For most tactical, outdoor, and premium bag applications, 500D is often the more versatile and commercially popular choice.

4) Is Nylon 500D Cordura waterproof?

The base fabric itself is not automatically waterproof. Water resistance mainly depends on finishes and construction, such as:

PU coating

TPU coating or lamination

DWR (durable water repellent)

Seam design and product structure

Choosing the right coating system is key for outdoor and wet-environment products.

5) What are the most common coatings for 500D Cordura-style fabrics?

PU coating for cost-effective, broad-use performance

TPU coating/lamination for improved cold resistance and durability

Special finishes like flame retardant, IRR, antimicrobial, or anti-UV depending on the application and compliance needs.

6) What are the main advantages of Nylon 500D Cordura?

High abrasion resistance for long-lasting surface durability

Strong tear strength to withstand harsh handling

Good structural integrity for pack panels and high-wear zones

A reliable balance of toughness and weight for mass-market and premium products.

7) What are typical applications?

Nylon 500D Cordura fabric is commonly used for:

Tactical backpacks, pouches, and load-bearing gear

Outdoor packs and accessories

Motorcycle and cycling gear

Industrial tool bags and protective covers

High-wear travel and daily-use bags.

8) What weave structures are commonly used?

Most 500D durable nylon fabrics use plain weave for stability and abrasion resistance. Some suppliers also offer variations with different densities or weave tuning to adjust handfeel, stiffness, and performance.

9) How can buyers evaluate quality before bulk orders?

Ask for:

TDS/spec sheet (weight, density, tensile, tear, abrasion data)

Coating details and hydrostatic head if waterproof performance is needed

Colorfastness and lightfastness

Compliance documents if your market requires them

And always confirm batch consistency with sample approvals.

10) Is 500D Cordura suitable for lightweight products?

Yes — it’s often chosen specifically to achieve a durability-to-weight sweet spot. It can deliver premium rugged performance without the bulk and stiffness of heavier denier fabrics.

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055