Why This Topic Matters for B2B Buyers

If you’re sourcing fabrics for tactical backpacks, plate carriers, outdoor bags, motorcycle gear, workwear, military pouches, or rugged covers, you’ll hear two similar terms all the time:

Cordura® Brand Fabric

Cordura-Style Fabric

They can look almost identical on a product page, but the sourcing outcome can be very different—especially when you care about abrasion resistance, lot-to-lot consistency, compliance requirements, and long-term procurement stability.

This guide breaks down the differences in a factory-friendly and buyer-friendly way, so you can write clearer specs, reduce sampling risk, and avoid “same name, different performance” surprises.

Quick Definitions

What is Cordura® Brand Fabric?

Cordura® refers to a registered brand name used by mills and suppliers who produce fabric that meets the brand’s required standards and labeling rules (typically involving defined yarn types, construction, and quality control).

In most cases, when buyers ask for “real Cordura,” they want brand-labeled fabric with traceability and consistent performance.

What is Cordura-Style Fabric?

Cordura-style is a construction/performance description, not a brand. It usually means:

High-tenacity nylon (often nylon 6 or nylon 6.6)

Plain weave / basket weave / ripstop options

PU coating / DWR / TPU lamination (depending on end use)

Built to similar appearance and abrasion goals, but not sold under the Cordura® label

Cordura-style fabric can be excellent when made correctly—many professional buyers use it for cost-effective performance or non-brand restricted tenders.

Example product reference on our site:

👉 IRR camouflage Cordura-style option: 330D Nylon Cordura-Style IRR Camouflage Waterproof PU Coated

Cordura® vs Cordura-Style: Side-by-Side Comparison

| Comparison Point | Cordura® Brand Fabric | Cordura-Style Fabric |

|---|---|---|

| Identity | Brand-labeled fabric | Generic construction (style/type) |

| Traceability | Usually higher | Depends on supplier |

| Consistency | Very stable with strict QC | Can vary widely |

| Yarn Options | Typically controlled specs | Nylon 6 / Nylon 6.6 / blends possible |

| Testing Data | Often standardized + documented | Must be requested & verified |

| Pricing | Higher | More flexible |

| Best Fit | Premium brands, high consistency programs | Value + performance programs, flexible tenders |

7 Key Differences (What Impacts Your Product Outcome)

1) Brand Labeling vs. Construction Spec

The biggest difference is not “good vs bad”—it’s whether you’re buying a brand-controlled fabric or a Cordura-like construction.

If your customer requires brand labeling, then Cordura-style is not a substitute.

If your customer requires performance only, Cordura-style may be the smarter sourcing move.

✅ Buyer tip: Put this sentence into your RFQ:

“Brand requirement: Cordura® label required / not required.”

2) Nylon 6 vs Nylon 6.6 (Strength & Heat Stability)

Cordura-style fabrics can be made using different polymers:

Nylon 6.6: typically better in heat stability and strength retention (often preferred for heavy-duty gear)

Nylon 6: commonly used and more cost-optimized

Some buyers assume all “Cordura” equals nylon 6.6—this is not always true unless clearly specified.

✅ What to specify:

“High-tenacity nylon 6.6 filament yarn” (if you need it)

Or “High-tenacity nylon (6/6.6 acceptable)” for flexibility

3) Denier & GSM (Real Durability Starts Here)

For bags and tactical gear, the most common families are:

330D: lighter weight, good for packs/panels

500D: balanced durability, mainstream tactical standard

1000D: heavy-duty, high abrasion zones

But denier alone is not enough—GSM and weave matter.

✅ Recommended spec format:

“500D, high-tenacity, 2×2 basket weave, ~260gsm, PU coated (2 layers).”

If you’re building SKUs for different market tiers, consider linking buyers to your internal fabric options hub:

Browse Cordura-Style Fabric Options (internal link suggestion)

500D Tactical Fabric Options (internal link suggestion)

1000D Heavy Duty Options (internal link suggestion)

4) Weave Structure (Plain vs Basket vs Ripstop)

Weave is one of the biggest reasons two “500D Cordura” fabrics perform differently.

Plain weave: smooth appearance, stable, widely used

2×2 basket weave: classic rugged look, good abrasion resistance

Ripstop: grid reinforcement, improved tear behavior, popular in lightweight gear

✅ If your sewing line and coating process need stability, include:

“Weave: plain/basket/ripstop (required).”

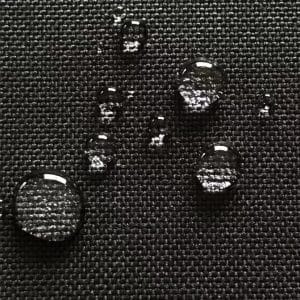

5) Coating & Backing (PU, TPU, Acrylic, or Custom)

Many disputes happen because buyers think “waterproof” is universal.

Common B2B options:

PU coating (cost-effective, good for bags, customizable thickness)

TPU lamination (soft handfeel, higher hydrostatic head, premium waterproof)

DWR on face (water repellency, not waterproof alone)

If you sell to tactical customers, you may also need:

IRR / NIR compliant coating & dyeing

Flame retardant (FR) finishes for specific requirements

Helpful internal reference paths:

IRR / NIR Tactical Fabric Solutions (internal link suggestion)

Flame Retardant Cordura-Style Fabrics (internal link suggestion)

6) Testing & Certifications (Performance is Measured, Not Promised)

For B2B purchasing, you want to see test methods—not vague claims.

Common tests buyers request:

Abrasion resistance (Martindale / Taber depending on market)

Tear strength

Tensile strength

Color fastness (washing, rubbing, light)

Hydrostatic head (if waterproof performance matters)

✅ If you are comparing Cordura® vs Cordura-style fairly, ask both suppliers for test reports based on the same standards.

7) Supply Chain Stability & Lot Consistency

For long-term B2B projects (uniform programs, government supply, multi-year contracts), stability matters:

Can the supplier keep shade consistency across lots?

Can they offer traceability for claims?

Can they maintain same coating recipe across repeats?

Cordura-style suppliers vary—some are highly professional, others are purely price-driven.

✅ Smart procurement approach:

Use a clear QC checklist + PP sample approval instead of relying only on naming.

Which One Should You Choose? (Fast Decision Guide)

Choose Cordura® Brand Fabric if:

Your customer contract requires brand labeling

You sell premium tactical/outdoor products

You want predictable repeatability with minimal debate

You need strong brand-backed market recognition

Choose Cordura-Style Fabric if:

You want best cost-to-performance

Your tender/spec is performance-based, not brand-based

You need custom coating / custom IRR / custom print

You want flexible sourcing for multiple markets

Buyer Checklist: How to Avoid “Same Name, Different Fabric”

Before approving bulk production, ask for:

Complete specification sheet

Denier, GSM, weave, yarn type, coating type, coating weight

Lab test report (same standard for comparisons)

abrasion, tear, tensile, waterproof data (if required)

Color control method

Pantone / shade band / master sample + tolerance

PP sample

verify handfeel + sewing performance + coating adhesion

Bulk roll inspection terms

defect points standard, roll length, joint allowance

Repeat order guarantee

minimum order for same-dye lot planning, lead time

If you’re sourcing IRR camouflage or tactical prints, start from a controlled option like:

👉 330D Nylon Cordura-Style IRR Camouflage Waterproof PU Coated

RFQ Template (Copy/Paste for Faster Quoting)

Here’s a B2B RFQ format that gets accurate pricing and fewer revisions:

Product: Cordura® brand / Cordura-style fabric

Denier: 330D / 500D / 1000D

Yarn: high-tenacity nylon 6.6 filament (or nylon 6 acceptable)

Weave: plain / 2×2 basket / ripstop

GSM: target ___ gsm (±5%)

Coating: PU (___ layers) / TPU lamination / acrylic

Waterproof: hydrostatic head target ___ mm (if required)

Finish: DWR / FR / IRR-NIR (if required)

Color/Print: solid / camouflage print (provide pattern)

MOQ: ___ meters per color

End use: backpacks / pouches / workwear / tactical gear

Testing: abrasion + tear + color fastness (please provide report)

Delivery term: EXW / FOB / CIF

Shipment: air / sea

FAQ (B2B Sourcing Questions)

1) Is Cordura® brand fabric always better than Cordura-style?

Not automatically. Cordura® brand fabric is brand-labeled and typically more consistent, but high-quality Cordura-style can match performance when the specs and QC are controlled.

2) Can Cordura-style fabric be nylon 6.6?

Yes. Many Cordura-style options use high-tenacity nylon 6.6 filament yarn, especially in 500D and 1000D ranges. Always specify polymer + yarn type in your RFQ.

3) Why do two suppliers quote “500D Cordura fabric” with very different prices?

Because “500D” alone doesn’t define yarn quality, weave structure, GSM, coating type, coating weight, or finishing. Pricing can also vary by dyeing quality and inspection standards.

4) What’s the best option for tactical backpacks: 500D or 1000D?

For most tactical backpacks, 500D offers an ideal balance of durability and weight. 1000D is better for extreme abrasion areas or heavy-duty military use.

5) Do I need IRR / NIR compliance?

Only if your end market requires signature management (certain tactical/military applications). If required, request IRR/NIR dyeing + testing method clarity, not just a verbal promise.

6) What coating is best for bag fabric?

For most B2B bag applications, PU coating is the best cost-to-performance choice. For premium waterproof gear, consider TPU lamination.

7) How do I verify I’m getting consistent quality in bulk orders?

Use a system: PP sample approval + roll inspection standard + shade band control + repeat-order process. This is more reliable than trusting naming alone.

8) Can you produce custom camouflage patterns?

Yes—many projects use custom camouflage prints with PU coating and optional IRR/NIR performance (depending on requirement). Provide a pattern file or reference sample.

Final Takeaway (Simple & Procurement-Friendly)

Cordura® brand fabric = best when brand labeling and consistency are mandatory

Cordura-style fabric = best when performance specs matter most and you want flexible cost control

The winning strategy for B2B buyers is not guessing by name—it’s locking the specification + verifying test data + controlling bulk consistency.

Call to Action (Get a Fast Quote + Spec Support)

If you’re sourcing Cordura® brand fabric or high-performance Cordura-style fabric for tactical/outdoor/workwear products, we can support you with:

330D / 500D / 1000D options

PU coating / TPU lamination / custom backing

IRR/NIR camouflage printing

Flame-retardant finishes (on request)

Lab test support + consistent bulk production

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: https://www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055