Nylon 500D Ripstop Cordura Fabric Multicam Camouflage Wateproof Pu Coating

Nylon 500D Ripstop Cordura-style fabric in Multicam camouflage with waterproof PU coating is a tactical-grade textile engineered for lightweight durability, tear resistance, and outdoor water protection. It is widely used for tactical backpacks, MOLLE pouches, plate carrier accessories, outdoor covers, and rugged bag manufacturing where strength-to-weight performance matters.

With ripstop reinforcement, this 500D nylon fabric helps stop small cuts from turning into large tears—ideal for field gear and high-mobility equipment.

✅ 500D ripstop nylon = lighter than 1000D, stronger than standard apparel fabrics

✅ Multicam camouflage print for tactical market demand

✅ Waterproof PU coating for rain & splash resistance

✅ Stable bulk consistency for B2B supply programs

✅ OEM options available: IRR / DWR / coating level / custom patterns

Reply within 12–24 hours • MOQ-friendly • Fast sampling

Note: “Multicam®” is a trademark of its respective owner. We supply Multicam-style camouflage printed fabrics for industrial/tactical applications.

Quick Specs

Final specifications can be customized based on your target handfeel, waterproof rating, and sewing requirements.

Base Fabric

Material: 100% Nylon (Nylon 6 / Nylon 6.6 available)

Denier: 500D × 500D

Weave: Ripstop

Weight Range: 250 GSM (depends on coating & construction)

Width: 150 cm (usable width)

Coating & Performance

Coating: Waterproof PU coating

Waterproof Rating (Hydrostatic Head):

Standard: 800 mmH₂O

DWR (Water Repellent): Optional

IRR / NIR: Optional

Order Info

MOQ: 500 meters per design (negotiable for sampling programs)

Lead Time: 20–30 days after sample approval

Packing: Roll packing with poly bag + woven bag (export standard)

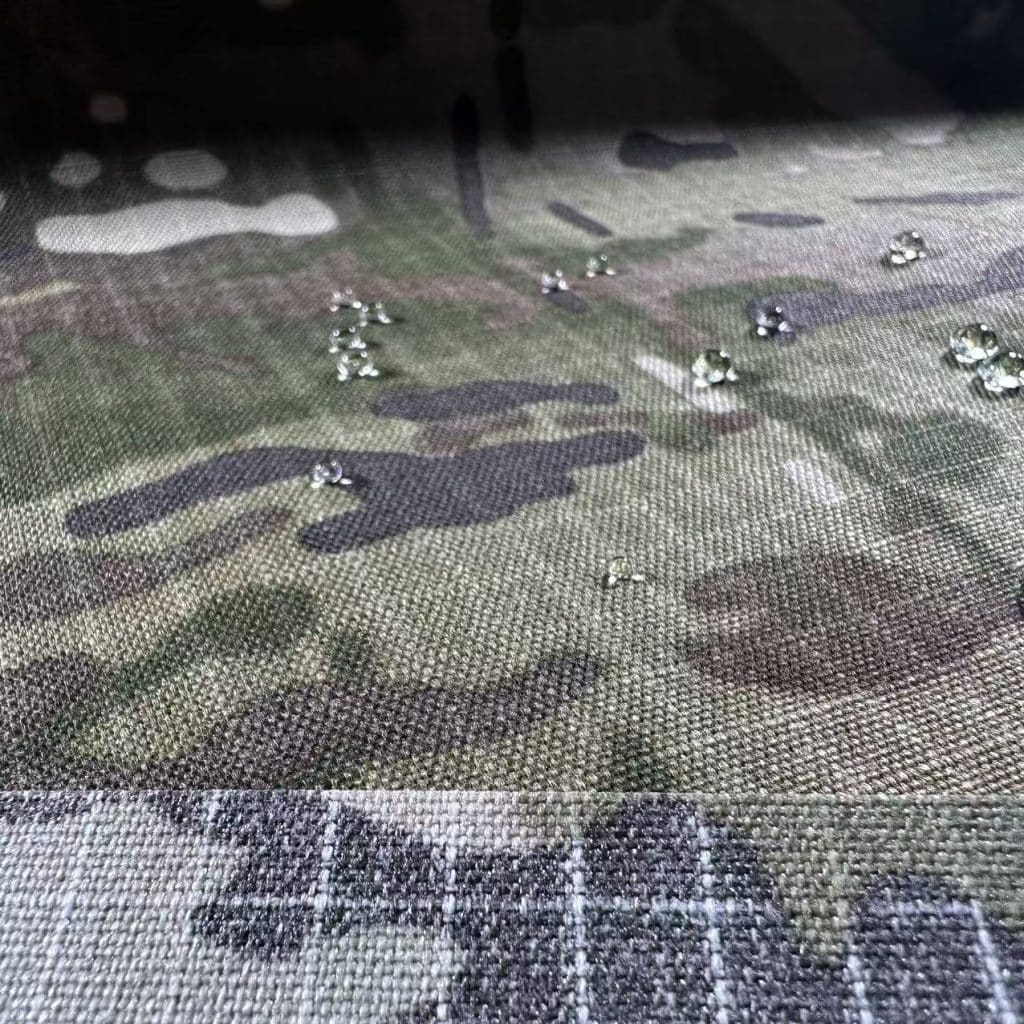

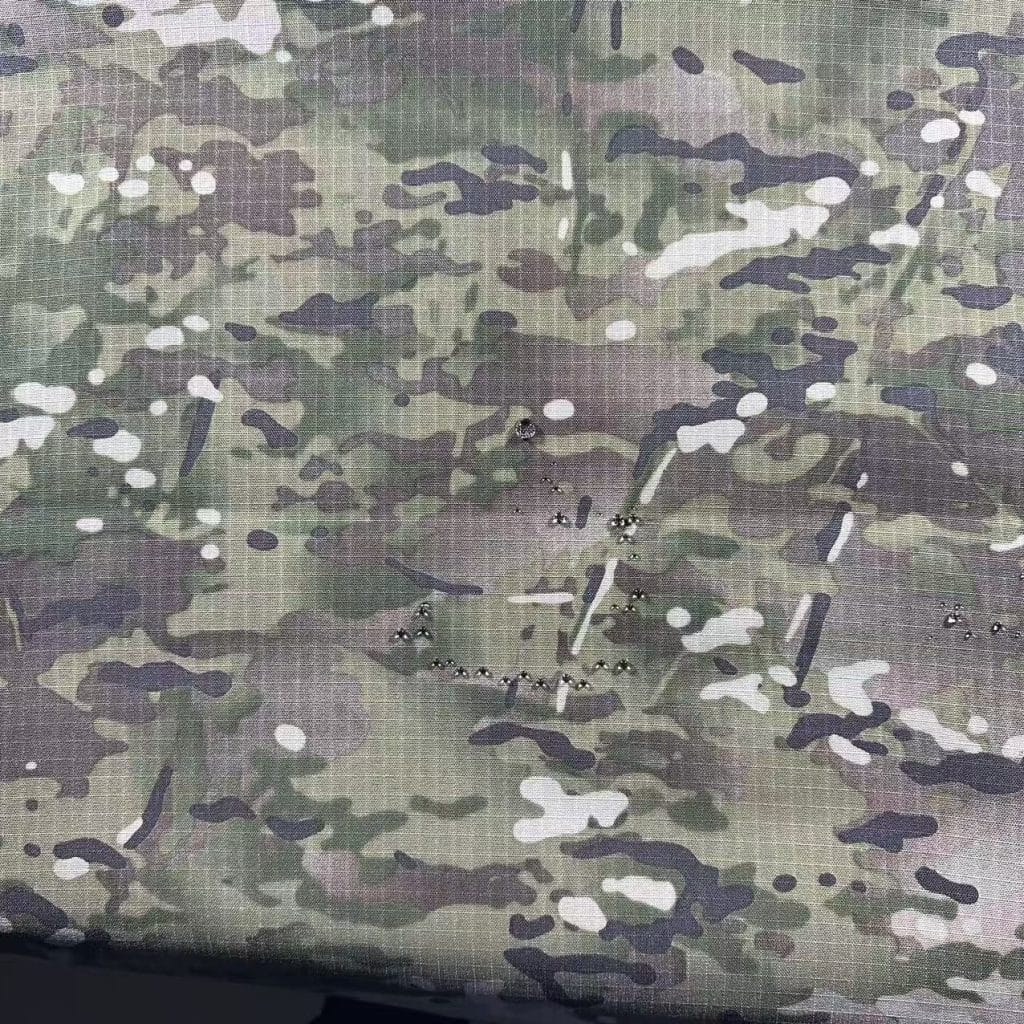

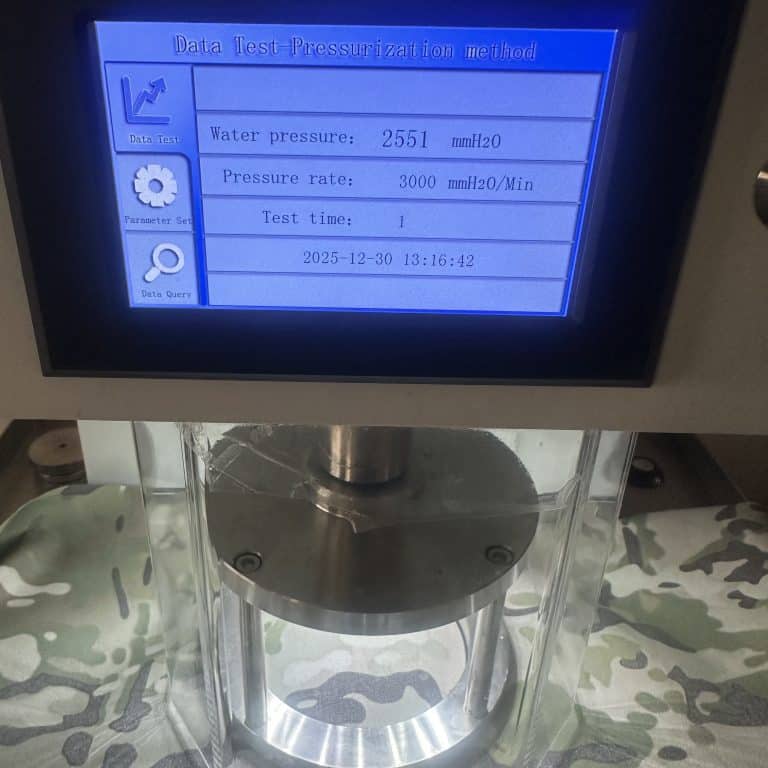

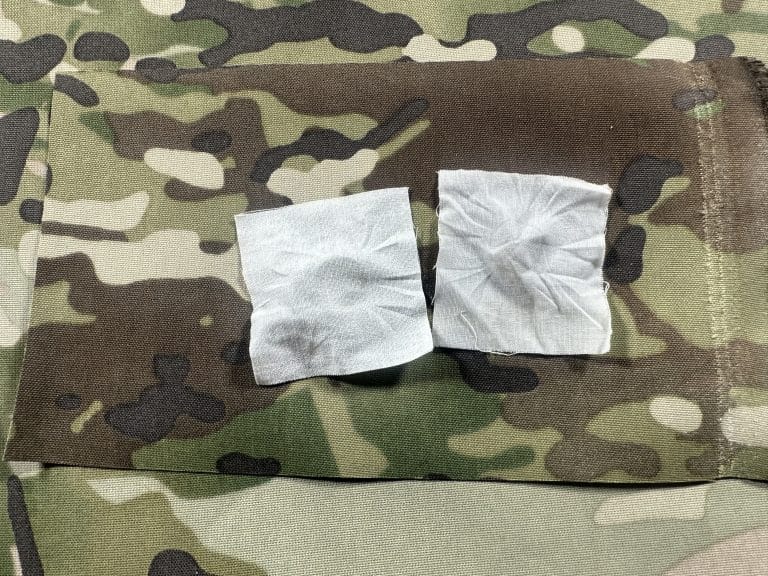

Waterproof Test Photo(Proof)

Nylon 330D Cordura Fabric IRR Camouflage Waterproof Pu Coating, Waterproof test photo (2500 mmH₂O) for reference. Actual performance depends on coating level and test method. Detailed test data is available upon request.

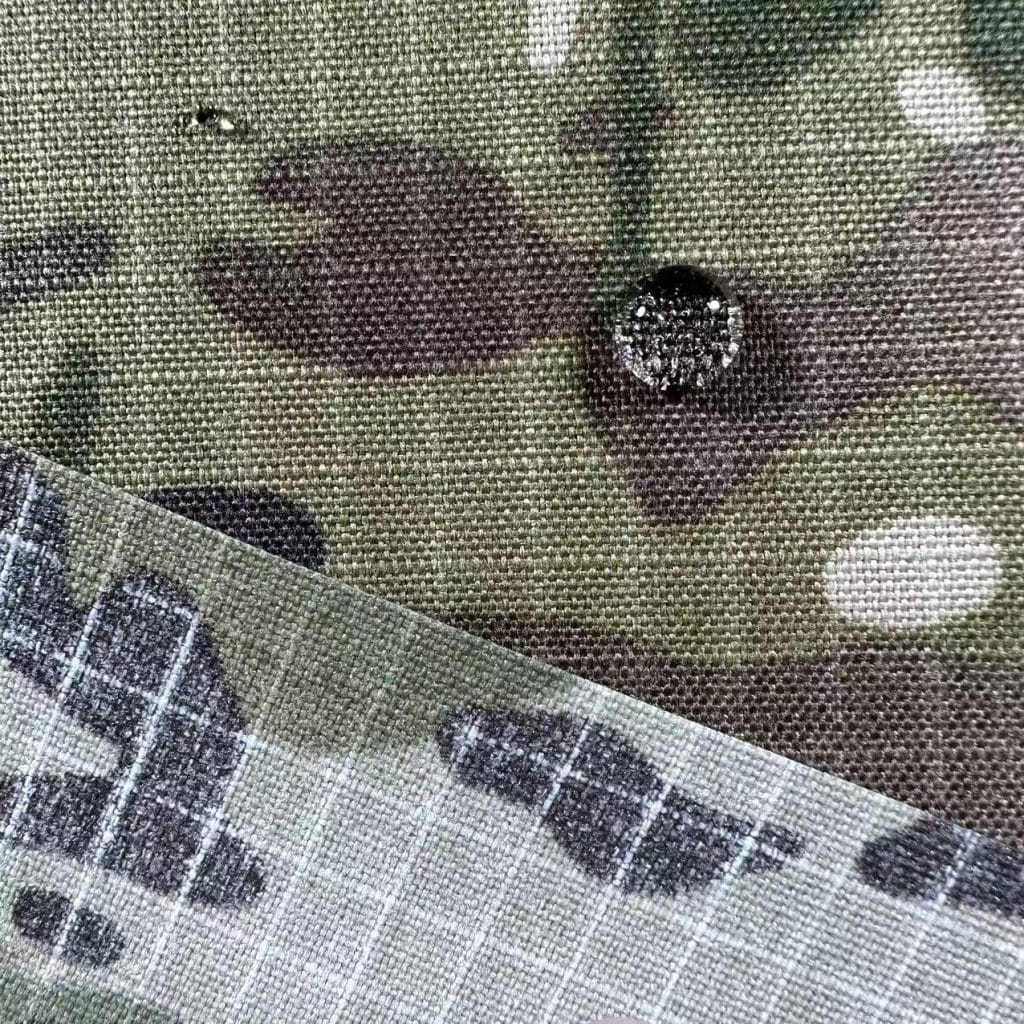

Color Fastness to rubbing

Color Fastness to Rubbing (Dry/Wet): Grade 4–5 / 4–5

Rubbing fastness test photo for reference. Results may vary by colorway and test method; detailed test information is available upon request.

Why Choose 500D Ripstop Cordura Fabric for Tactical Gear?

When buyers choose between 500D and 1000D, the real question is not “which is stronger,” but which performs best for the mission.

1) Ripstop Grid = Better Tear Control in Field Use

Ripstop construction is designed to:

reduce tearing after puncture

prevent small damage from spreading

improve overall reliability in rugged conditions

This is especially important for tactical and outdoor gear that gets scraped, folded, and pulled repeatedly.

2) 500D = Best Balance of Strength and Weight

500D is widely used for:

backpacks and assault packs

tactical pouches and organizers

lightweight plate carrier accessories

outdoor gear requiring mobility

Compared to 1000D, it reduces bulk and weight, making it easier for brands to build lighter, faster, more comfortable products.

3) Waterproof PU Coating = Practical Outdoor Protection

PU coating adds a protective layer against:

rain and moisture

splash conditions

wet ground contact

damp storage environments

If your product is used outdoors (hiking, tactical patrol, travel, training), waterproof PU coating helps improve end-user satisfaction and reduces complaint risk.

Waterproof PU Coating Options (Choose by End Use)

Not all “PU coated 500D” is the same. Coating level changes handfeel, waterproofness, and structure.

Light PU Coating (Flexible / Easy Sewing)

Recommended for:

general tactical bags

medium-duty pouches

outdoor backpacks with lighter weight goals

Medium PU Coating (Balanced Waterproof + Structure)

Recommended for:

tactical packs with reinforcement zones

MOLLE pouches that need better body/shape

duty gear organizers

Heavy PU Coating (Maximum Water Barrier)

Recommended for:

covers, outdoor storage bags

equipment protection applications

wet-environment accessories

Tip: If you need waterproof performance beyond standard PU coating, tell us your target mmH₂O and end-use. We can recommend the most cost-effective structure.

Multicam Camouflage Print for B2B Programs

For many buyers, camouflage is not only a look—it is a market requirement.

Our Multicam-style printed ripstop Cordura fabric focuses on:

stable repeat consistency

controlled shade difference between lots

durable print bonding for long-term use

compatible coating options for field gear

If you have a long-running program, we can support bulk continuity and consistent quality.

Applications

Nylon 500D Ripstop Multicam waterproof PU coated fabric is widely used for:

Tactical backpacks & assault packs

MOLLE pouches / duty gear organizers

Plate carrier accessory panels

Outdoor equipment covers & storage bags

Rugged travel duffels and day packs

Medical/utility tactical bags

Motorcycle luggage and field kits

Hunting gear & outdoor accessories

If you tell us the finished prod

Customization Options

We support real B2B customization for tactical manufacturers:

Coating level: light / medium / heavy PU

Waterproof target: 1000–10,000+ mmH₂O

DWR finish: optional (C6 / C0 on request)

IRR / NIR treatment: optional for military programs

Camouflage patterns: Multicam-style / custom artwork / OEM patterns

Handfeel tuning: stiffer for structure / softer for folding

Color matching: controlled shade & batch management

Packing & labeling: roll ticketing, barcode labels, export packing

Quality & Consistency

We keep bulk quality stable through coating adhesion checks, shade control, print repeat verification and waterproof performance evaluation (by request). If your program requires lab reports, we can support third-party testing after sample approval.

greige fabric inspection

coating consistency control

shade and print repeat verification

roll inspection and packing records

support for third-party testing if required

Stable Bulk Consistency

Fast Sampling

Export Packing & QC Records

Need QC Evidence?

Ask for in-house QC records or third-party test options

Ordering Information

MOQ: 500 m per design (negotiable for development)

Sampling: A4 swatch / meter sample available

Lead Time: 20–30 days after sample approval

Payment: T/T (other options for long-term partners)

Shipping: express / air / sea available

FAQ

Is this genuine CORDURA®?

This is a Cordura-style nylon fabric for tactical and outdoor applications.

If you require branded CORDURA®, please tell us your program requirement and we can discuss available options.What’s the advantage of ripstop vs plain weave?

Ripstop includes a reinforced grid that improves tear resistance and helps prevent small cuts from spreading.

Is 500D strong enough for tactical backpacks?

Yes. 500D is widely used for tactical backpacks and pouches where weight control and mobility are important.

If you need maximum abrasion resistance, 1000D may be better for high-wear reinforcement panels.What waterproof rating can you supply?

Common options 800 mmH20

Can you supply IRR / NIR for military projects?

Yes, IRR is optional for selected colors and projects. Share your target requirement and we will check feasibility.

Can you do custom camouflage patterns?

Yes. We can produce custom printed patterns based on your artwork files and program requirements.

Does PU coating affect breathability?

Yes. PU coating provides water resistance but is not breathable, which is ideal for bags, pouches, and covers.

How do we start sampling?

Send us:

application (backpack / pouch / cover)

target waterproof rating

camouflage requirement (Multicam-style / custom)

estimated order quantity

We’ll recommend the best spec and arrange samples.

Request a B2B Quote & Samples

Tell us your application (backpack/pouch/uniform), target waterproof rating, IRR requirement and expected order volume. We’ll reply with recommended specs, pricing and sampling options.

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: https://www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055