Nylon 1000D Multicam Camouflage Cordura Fabric Waterproof PU Coating

1000D Multicam camouflage Cordura-style nylon fabric with waterproof PU coating, engineered for heavy-duty tactical backpacks, plate carrier panels, load-bearing pouches, and rugged outdoor equipment. Built for high abrasion zones, long-term field use, and stable bulk consistency in B2B programs.

Multicam camouflage print for professional tactical appearance & stable repeat

Waterproof PU coating for rain & splash protection

1000D high-tenacity nylon base for extreme durability and tear resistance

Optional IRR / DWR / FR finishes for military & law-enforcement projects

OEM pattern support + MOQ-friendly production + export-ready packing

Reply within 12–24 hours • MOQ-friendly • Fast sampling

Quick Specs

Material: 100% Nylon (Nylon 6 / Nylon 6.6 available)

Denier: 1000D × 1000D

Weave: Plain Weave

Weight Options: 340 GSM

Width: 150 cm (usable width)

Print: Multicam Camouflage (OEM patterns supported)

Coating / Backing: Waterproof PU Coating (2–3 times)

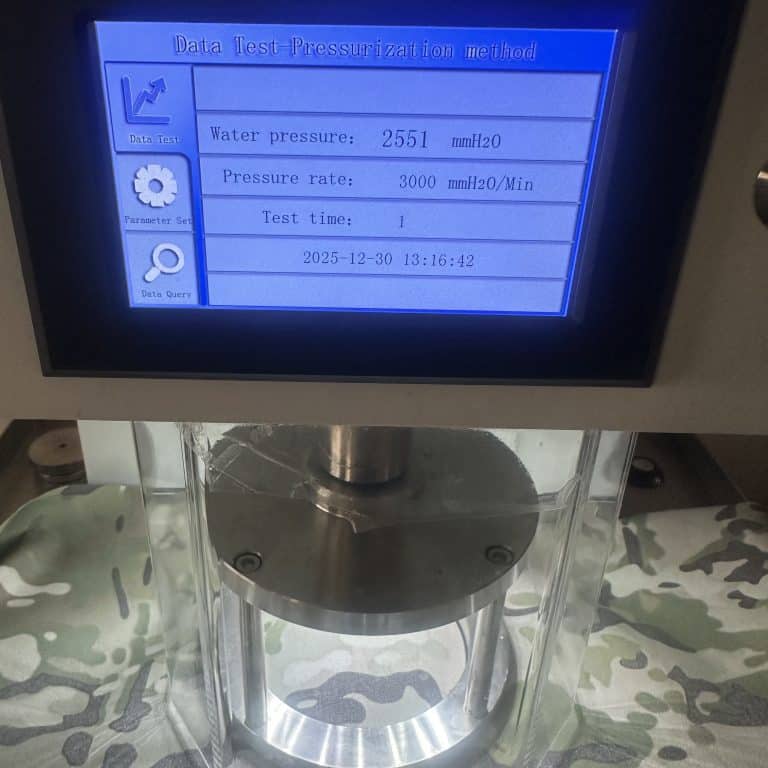

Waterproof Rating (Hydrostatic Head):

Standard: 800 mmH₂O

Typical upgraded option: 800–1500 mmH₂O

DWR (Water Repellent): 4-5

IRR (Infrared Reflectance Reduction): 850NM 940 NM

Breathability: No (PU coated)

MOQ: 500 meters per design (negotiable for development programs)

Lead Time: 20–30 days after sample approval

Packing: Roll packing with poly bag + woven bag (export standard)

Waterproof Test Photo(Proof)

Nylon 1000D Cordura Fabric IRR Camouflage Waterproof Pu Coating, Waterproof test photo (800 mmH₂O) for reference. Actual performance depends on coating level and test method. Detailed test data is available upon request.

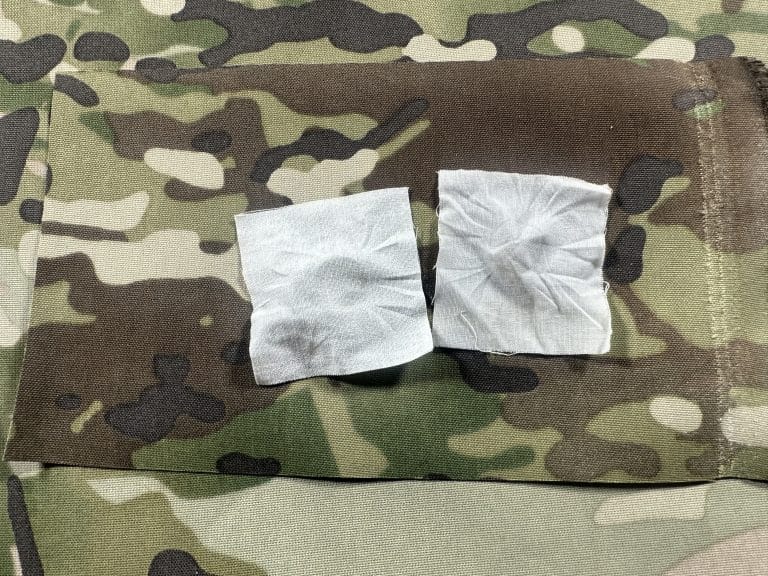

Color Fastness to rubbing

Color Fastness to Rubbing (Dry/Wet): Grade 4–5 / 4–5

Rubbing fastness test photo for reference. Results may vary by colorway and test method; detailed test information is available upon request.

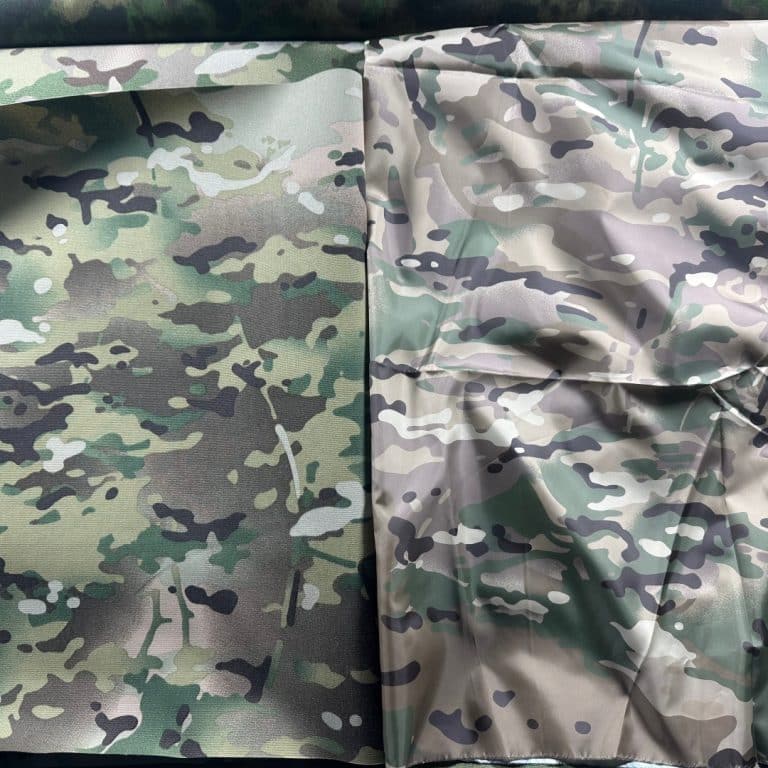

Visible Light vs 850nm NIR (IRR Finishing Comparison)

The following photos show the same fabric samples under normal visible light and under 850 nm near-infrared (NIR) illumination. This comparison helps illustrate differences in NIR reflectance / brightness behavior between samples.

IRR finishing Fabric, and regular printing Fabric under Visible Light

IRR finishing Fabric, and regular printing Fabric under 850 nm NIR

1000D IRR Camouflage Cordura-Style Fabric Video

In this video, you can check the fabric texture, print repeat, and PU-coated backing of our 1000D Cordura-style nylon with IRR camouflage. If you need a specific waterproof rating, handfeel, or IRR requirement, send your use case and we’ll recommend the best specification and provide samples.

Why 1000D Multicam PU Coated Cordura Fabric Converts for Tactical Buyers

When your customer is making tactical gear, the fabric is not a “visual choice”—it is a failure-point decision.

1) Built for high-abrasion, high-load zones

1000D is widely used for:

Tactical backpacks & assault packs

Load-bearing pouches and modular MOLLE systems

Reinforcement panels where 500D is not enough

Field covers, drag bags, and heavy-duty organizers

If your product gets dragged, scraped, and used daily, 1000D gives the confidence buyers want.

2) Waterproof protection without changing your product structure

PU coating provides a practical waterproof barrier that helps resist:

Rain exposure

Splash and wet ground contact

Mud, moisture, and outdoor storage conditions

For bag makers and tactical equipment brands, this means less water penetration risk and more stable end-user feedback.

3) Multicam print stability matters in real bulk production

“Multicam fabric” is common online. But procurement teams care about:

Print repeat stability

Shade matching consistency

Bulk-to-bulk color control

Coating consistency from lot to lot

We support shade control + bulk inspection records, which is why this fabric works for long-running B2B programs.

Waterproof PU Coating Options (Choose by End Use)

Not all PU coated 1000D is the same. You can select coating level by your target application:

Light PU coating (Flexible)

Best for:

Standard tactical backpacks

Medium-duty pouches

General outdoor bags

Medium PU coating (Balanced)

Best for:

Heavy tactical packs

Reinforced MOLLE panels

Field tool bags

Heavy PU coating (Maximum waterproof)

Best for:

Wet-environment covers

Outdoor storage bags

Equipment protection gear

Tip: If your product uses seams and stitching, waterproof performance depends on construction and seam design. If you need higher waterproof reliability, ask us about upgraded coating or TPU laminated solutions.

Applications

This 1000D Multicam waterproof Cordura-style fabric is widely used for:

Tactical backpacks & assault packs

Military & law-enforcement MOLLE pouches

Plate carrier panels & reinforcement zones

Duty gear bags, range bags, rifle bags

Outdoor equipment covers and storage organizers

Motorcycle luggage and rugged travel duffels

Heavy-duty tool bags and industrial protective packs

Customization Options

We support real B2B customization—so you can match your market needs and procurement requirements:

Camouflage patterns: Multicam-style / A-TACS-style / custom artwork

IRR option: Available for specific colorways (confirm target requirement)

Coating level: light / medium / heavy PU coating

DWR finish: optional (C6 / C0 available by request)

Flame retardant (FR): optional (project-based)

Handfeel tuning: stiffer for structure / softer for sewing and folding

Labeling & packing: export ticketing, inspection length, roll packing records

Quality & Consistency

We keep bulk quality stable through coating adhesion checks, shade control, print repeat verification and waterproof performance evaluation (by request). If your program requires lab reports, we can support third-party testing after sample approval.

Incoming raw yarn/fabric checks

Coating adhesion & peel test

Shade control (lab dip / bulk approval)

Print repeat verification

Waterproof performance test (upon request)

Final inspection & roll packing record

Stable Bulk Consistency

Fast Sampling

Export Packing & QC Records

Need QC Evidence?

Ask for in-house QC records or third-party test options

Ordering Information

MOQ: 500 m/color, depends on pattern

Lead Time: 25-30 days after sample approval

Samples: A4 swatch or yardage sample available

Packing: Roll packing with poly bag + woven bag (export standard)

FAQ

Is this genuine CORDURA®?

This is Cordura-style nylon fabric engineered for tactical and outdoor applications.

If you need branded CORDURA®, we can discuss options based on your program requirements.Is 1000D better than 500D?

1000D is stronger and more abrasion-resistant, suitable for heavy-duty zones.

500D is lighter, often used where weight saving matters.What waterproof rating can you offer?

Standard: 800 mmH₂O

Upgraded: 1000–1500 mmH₂O

Will PU coating crack in cold weather?

Standard PU coating works well for most bag applications.

If your product will be used in extreme cold or needs higher flex durability, tell us your temperature range—we can recommend a better coating spec.Can you add DWR on top of PU coating?

Yes. DWR is optional depending on your market needs and compliance requirements.

Does Multicam print always include IRR?

Not always. IRR depends on pigment recipes and colorway control.

If your program requires IRR, share your target standard and we will confirm feasibility.What is typical MOQ and lead time?

Our regular MOQ is 500 meters per design, lead time is 25-30 days. We can discuss further if there is any problem with you.

How do we start sampling?

Send:

Target application (backpack / pouch / plate carrier / cover)

Required waterproof rating

Print pattern requirement (Multicam / custom)

Estimated order volume

Then we will recommend a baseline spec and ship samples.

Request a B2B Quote & Samples

Tell us your application (backpack/pouch/uniform), target waterproof rating, IRR requirement and expected order volume. We’ll reply with recommended specs, pricing and sampling options.

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: https://www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055