Waterproof 330D Cordura Nylon: PU vs TPU, DWR, IRR, FR & UV Finishes Explained

“Is it waterproof?” is one of the most common questions buyers ask—yet it’s also the most misunderstood.

330D Cordura-type nylon can be engineered from light water resistance all the way to high waterproof performance, depending on the coating/lamination system and finishing package.

In this guide, I’ll break down PU vs TPU, explain what DWR actually does (and doesn’t), and show how to specify IRR/FR/UV finishes for tactical or industrial projects—without overpaying or under-specifying.

For full product specs and our available variants, see:

Nylon 330D Cordura Fabric

1) First, define “waterproof” for your product (not for the fabric)

A fabric’s waterproof rating (hydrostatic head, “mm”) only matters in context.

Ask yourself:

Will this bag face light rain or sustained rain exposure?

Will it be used for commuting or for hiking/trekking?

Is it for an outer shell panel or an inner compartment?

Do you need waterproofing for the fabric only, or also for seams and zippers?

Even a high waterproof fabric will leak if seams aren’t sealed or construction isn’t designed for wet conditions.

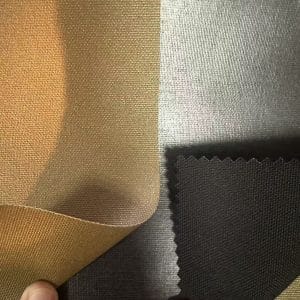

2) PU coating on 330D: the practical everyday solution

On our 330D range, PU coating (1–3 layers) is the most common, economical choice.

Typical waterproof level: ~300–2000 mm, depending on structure and layer count.

Best applications for PU-coated 330D

Commuter backpacks

Travel organizers, duffels

Laptop sleeves and daily bags

Pros

Cost-effective

Stable and widely available

Easy to tune for stiffness and body

Cons / watch-outs

PU hydrolysis risk varies by formulation and storage conditions

“PU coated” is not one spec—layer count and resin quality matter

Buyer tip:

Don’t just ask “PU coated.” Ask:

“How many layers?” (1–3)

Target waterproof rating (mm)

Adhesion expectations and aging guidance

Whether you need “soft handfeel” or more structure

For higher waterproof needs, TPU lamination is the upgrade path.

Typical waterproof level: ~3000–8000+ mm, structure-dependent.

Best applications for TPU laminated 330D

Rain-exposed compartments on outdoor packs

Lightweight performance packs

“Cleaner backing” / premium feel products

TPU laminations often look smoother and can provide a cleaner, more technical aesthetic—especially when paired with a good face fabric and consistent lamination.

Buyer tip:

If you’re developing a “waterproof capsule” (like a top lid, front pocket, or internal dry compartment), TPU lamination is usually the more convincing story than simply adding more PU layers.

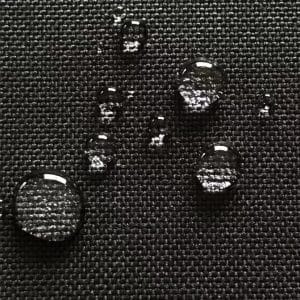

4) DWR finishing: what it does (and why you still want it)

DWR (Durable Water Repellent) improves surface beading and reduces “wet-out” on the face fabric.

What DWR does:

Helps water bead and roll off

Keeps the fabric looking cleaner in light rain

Reduces surface saturation, improving comfort and appearance

What DWR does NOT do:

It does not replace PU/TPU waterproof backing

It does not seal seams or zippers

Best practice:

For outdoor packs, a common combo is:

Face: DWR

Back: PU or TPU, chosen by waterproof requirement

5) IRR finishing: when tactical projects demand signature control

If your buyers are in military or professional law enforcement procurement, you may hear: IRR (Infra-Red Reduction).

Our 330D line supports Multicam-style 330D with IRR finishing on request for tactical applications.

When IRR matters

Professional tactical gear projects

Uniform/gear systems where compliance is required

Certain export or tender requirements

When IRR is unnecessary

Civilian outdoor packs

Lifestyle/urban backpacks

Travel organizers

Buyer tip:

Always confirm:

The required test method/standard (if specified)

Whether the requirement applies to the print, the dye, or the full construction

Batch consistency expectations

6) FR (flame retardant) treatment: niche, but critical in some markets

For industrial or protective applications, FR treatment can be requested for 330D.

FR is relevant for:

Industrial protective gear

Certain workwear accessories

Special protection environments

Buyer tip:

“FR” is never one thing. Clarify:

FR standard required by the market (if applicable)

Whether FR must be durable after washing

Any restricted substances requirements

7) UV resistance, calendaring, printing: performance + aesthetics

Depending on where the bag will be used, UV resistance can help maintain appearance. We also support optional printing and calendaring.

UV-resistant: helpful for prolonged sun exposure

Printed / camouflage: brand styling or tactical pattern programs

Calendared: can improve surface feel/appearance depending on target look

8) A decision matrix: which finish package should you choose?

If you make commuter backpacks (daily rain, city use)

Weave: Plain

Backing: PU coating (1–2 layers)

Face: DWR

Goal: practical water resistance + good handfeel

If you make lightweight outdoor packs (regular rain exposure)

Weave: Plain or ripstop

Backing: TPU lamination

Face: DWR

Goal: higher waterproof + performance feel

If you make tactical accessories (light-duty MOLLE pouches)

Weave: Ripstop or plain

Options: IRR, printed camouflage

Backing: PU or TPU depending on environment

If you make industrial/protective accessories

Add: FR on request

Confirm compliance requirements early

9) How to write a 330D waterproof inquiry that gets fast, accurate quotes

Copy/paste and edit:

Subject: Inquiry – 330D Cordura-Type Nylon for Backpack (PU/TPU + DWR)

Hello,

We are sourcing Nylon 330D Cordura-type fabric for backpacks.

Please quote based on the following:

Yarn: High-tenacity Nylon 6 (or Nylon 66 if recommended)

Denier: 330D

Weave: Plain (or Ripstop)

Weight target: ___ gsm (within 160–220gsm range)

Width: 58/60″

Backing: PU (___ layers, target ___ mm) or TPU lamination (target ___ mm)

Face finish: DWR

Color: Pantone ___ / Black / Coyote / etc.

Quantity: ___ meters per color (MOQ?)

End use: commuter backpack / lightweight outdoor pack / tactical pouch

Please share:

TDS + test data (tensile, tear, abrasion, waterproof)

Lead time and sample availability

Thank you.

10) FAQ (for snippets + conversion)

Q1: Is 330D Cordura fabric waterproof by itself?

Water resistance depends mainly on the backing system (PU or TPU) and construction.

Q2: PU or TPU—what should I pick for backpacks?

PU is economical for daily bags; TPU is better for higher waterproof demand and premium handfeel.

Q3: What waterproof rating can I expect?

PU: ~300–2000mm; TPU: ~3000–8000+mm depending on structure.

Q4: What does DWR do?

DWR improves surface beading and reduces wet-out; it doesn’t replace PU/TPU waterproofing.

Q5: Can you do IRR or FR on 330D?

Yes—IRR and FR options are available for specific project requirements.

Conversion

For specs, coating options, MOQ, and to request free swatches/TDS: Nylon 330D Cordura Fabric

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: https://www.cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055