When buyers search for tactical backpacks or plate carriers, they often encounter two denier levels repeatedly: 500D Cordura and 1000D Cordura. Both are famous for their durability and are widely used in military, police, and outdoor gear – but which one is truly better for your application?

The short answer:

- 500D Cordura fabric is lighter, more flexible, and still very strong – making it ideal for modern tactical gear where weight and mobility are crucial.

- 1000D Cordura fabric is heavier, stiffer, and highly abrasion-resistant – ideal for high-abuse, heavy-duty gear or customers who value “tank-like” toughness and a rugged handfeel.

In this article, we’ll compare 500D vs 1000D Cordura specifically for tactical backpacks and plate carriers.

1. What Does “Denier” Actually Mean?

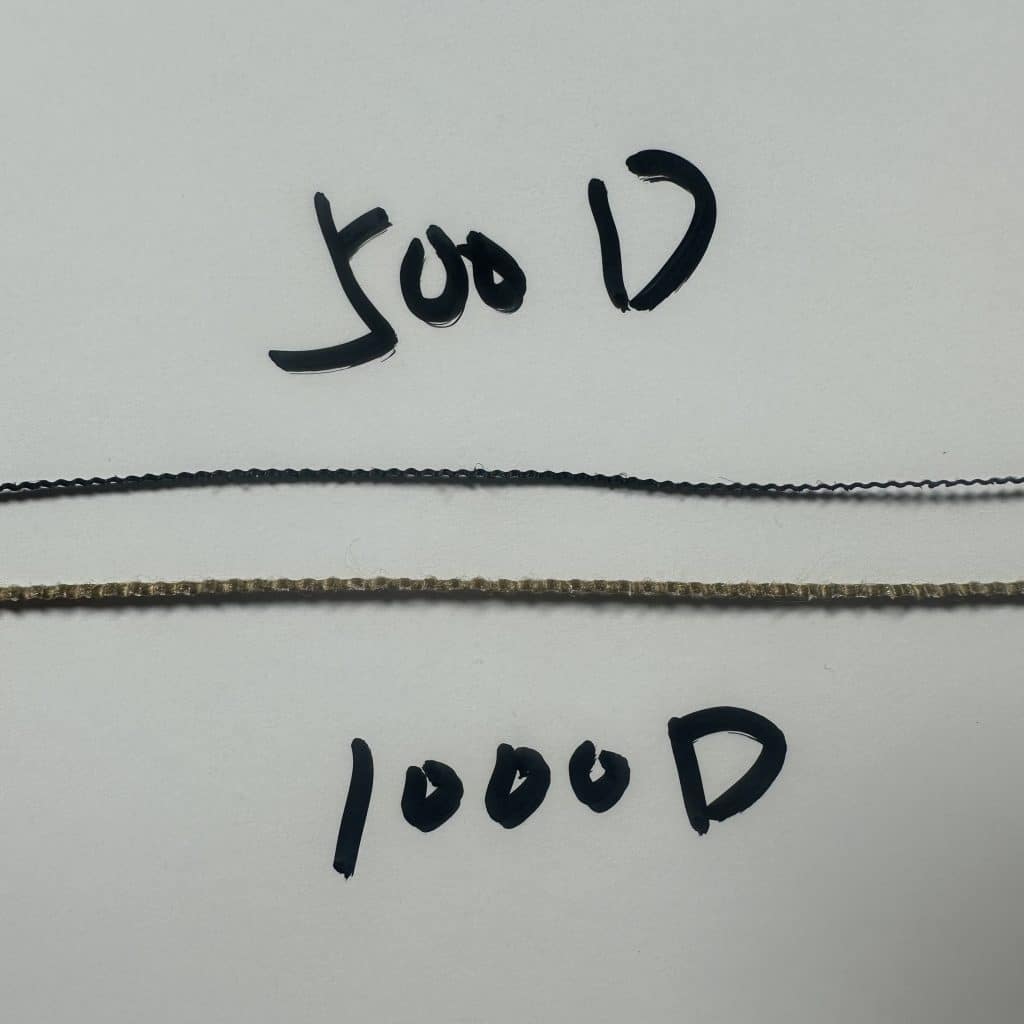

“Denier (D)” is a unit that describes the linear mass density of fibers – technically, grams per 9,000 meters of yarn.

- 500D Cordura → yarn is lighter and finer

- 1000D Cordura → yarn is about twice as heavy and thicker

In simple buyer language:

Higher denier = thicker yarn, usually stronger & more abrasion-resistant, but also heavier and bulkier.

Lower denier = lighter and more flexible, often more comfortable to wear, and easier to carry over long missions.

2. 500D Cordura: Lightweight Workhorse for Modern Tactical Gear

500D Cordura Nylon has become the standard for many military-style backpacks, plate carriers, chest rigs, and pouches used by modern armed forces and tactical brands.

Key Advantages of 500D Cordura

- Better Weight-to-Strength Ratio

- Compared with 1000D, 500D offers excellent strength at a much lower weight.

- For a full tactical backpack or plate carrier system, weight savings can be significant (especially when combined with multiple pouches, mags, armor plates, water, and tools).

- Lighter gear means less fatigue, better mobility, and improved performance over long missions.

- More Comfortable & Flexible

- The fabric is less stiff and more conforming to body curves.

- This is especially important for plate carriers and chest rigs, which stay close to the body for hours.

- Easier to sew into complex shapes and ergonomic designs, plus it drapes better.

- Quieter and Less “Crunchy”

- Compared with heavier 1000D, 500D usually produces less noise when moving.

- This matters in police, security, hunting, and special operations, where stealth is important.

- Modern Aesthetic

- Many premium tactical brands today use 500D Cordura for a sleek, professional look.

- It balances ruggedness and refinement, suitable for both duty use and everyday carry (EDC).

Typical Applications of 500D Cordura

- Tactical backpacks (24–48 hour packs)

- Plate carriers & chest rigs

- Modular pouches, admin panels, hydration carriers

- Law enforcement vests, patrol gear

- Outdoor & hiking backpacks where low weight is critical

3. 1000D Cordura: Maximum Ruggedness for Extreme Abuse

1000D Cordura Nylon is the “classic” heavy-duty fabric that built Cordura’s reputation. It is commonly associated with old-school military packs and bombproof equipment.

Key Advantages of 1000D Cordura

- Extreme Abrasion Resistance

- The thicker yarn and higher fabric mass give outstanding resistance to scuffs, dragging, and rough surfaces.

- Ideal for gear that will be thrown into truck beds, dragged on concrete, or used in training fields and harsh environments.

- High Tear & Tensile Strength

- Although both 500D and 1000D are strong, 1000D typically shows higher tear and tensile values in standard tests (like ASTM or ISO methods).

- For buyers who equate “higher number = stronger = safer,” 1000D is easy to sell emotionally.

- Rugged Tactical Handfeel

- 1000D Cordura has a coarser, more robust handfeel, which many users associate with “military-grade toughness.”

- Some brands deliberately choose it so that the gear feels indestructible in the hand.

- Perceived Durability and Brand Image

- For certain markets, just stating “1000D Cordura” on a hangtag or product page creates a high-end, bombproof image.

- If your target customers are military contractors, shooting ranges, or extreme users, this number can help marketing.

Typical Applications of 1000D Cordura

- Heavy-duty tactical backpacks for extreme environments

- Load-bearing vests & older-style plate carriers

- Duty belts, radio pouches, and ammo pouches are subjected to frequent friction

- Equipment cases, drag bags, range bags

- Motorcycle & luggage applications

4. Weight and Comfort: The Most Critical Factor for Plate Carriers

For plate carriers, weight and comfort are often more important than ultimate fabric strength, because:

- The plates themselves are already heavy (steel, ceramic, or composite).

- Operators often carry ballistic plates + mags + hydration + medical kit + communication devices.

- Missions can last many hours; shoulder and back fatigue are common.

Here, 500D Cordura usually has a clear advantage:

- It reduces the overall fabric weight of the carrier.

- It improves flexibility around the shoulders and torso.

- It helps the carrier contour to the body, improving comfort and lessening hotspots.

Many modern professional-grade plate carriers on the market have moved from 1000D to 500D or even hybrid constructions (e.g., 500D body + reinforced zones).

5. Durability & Lifespan: 500D vs 1000D in Real Use

Both 500D and 1000D Cordura are professional-grade tactical fabrics. In real-world use:

- 500D Cordura, when properly sewn and coated, usually offers more than enough durability for backpacks and plate carriers used by law enforcement, security, and serious civilians.

- 1000D Cordura will typically last longer in extremely abusive conditions, such as:

- Military infantry training with repeated crawling and dragging

- Heavy equipment carriage in vehicles and aircraft

- Frequent contact with rough surfaces (concrete, rocks, metal edges)

However, many modern tactical brands prefer to save weight and improve comfort by using 500D as the base fabric, then upgrading durability with:

- Reinforced bottom panels (double layer or 1000D patch)

- Bartacks and box-X stitching on straps and MOLLE webbing

- High-quality PU coatings for water resistance and tear strength stability

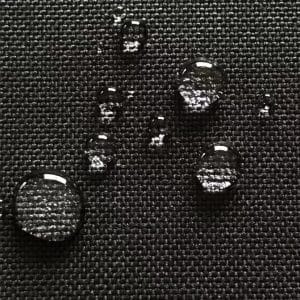

6. Water Resistance, Coatings, and Finishes

The denier number alone does not determine water resistance. What really matters is:

- PU or PVC coating weight (e.g., 1–2 PU coats on the back side)

- Optional DWR (Durable Water Repellent) finish on the face side

- Optional lamination (e.g., TPU films) for full waterproofness

- Optional IRR, FR, oil-repellent, or mildew-resistant finishes

Both 500D and 1000D Cordura can be produced with:

- Waterproof PU or TPU coating

- IRR (Infrared Reflective) finish for military camouflage

- Flame-retardant treatment for specific standards

7. Which Denier Is Better for Tactical Backpacks?

Let’s focus specifically on backpacks.

Choose 500D Cordura. When:

- Your customers carry the pack daily or for long missions, and weight is critical.

- The backpack is targeted at modern military, law enforcement, or EDC markets.

- You want a more refined appearance and comfortable carry.

- You may combine 500D body fabric with reinforced panels for high-wear areas.

Positioning angle on your website:

“500D Cordura: Ideal for modern tactical backpacks that require professional durability with reduced weight for long-term comfort.”

Choose 1000D Cordura. When:

- The backpack will be used in extreme rugged conditions: training schools, deployment, and heavy equipment loads.

- Your buyers value maximum abrasion resistance over low weight.

- You want a very rugged, traditional military look and feel.

8. Which Denier Is Better for Plate Carriers?

For plate carriers, the recommendation is clearer:

- In most cases, 500D Cordura is the better choice because:

- Weight reduction is critical.

- Comfort and flexibility around joints matter.

- The plate itself provides the ballistic protection; the shell must be durable, but not over-built and heavy.

When selling plate carrier fabrics, you can add a comparison chart and state:

- 500D for standard and professional carriers

- 1000D for special reinforcement or training-heavy use

9. 500D vs 1000D Cordura: Quick Comparison Table

| Parameter | 500D Cordura (Example) | 1000D Cordura (Example) |

|---|---|---|

| Yarn Denier | 500D Nylon | 1000D Nylon |

| Fabric Weight | Medium ( 200–260 gsm) | Heavy (300–380 gsm) |

| Abrasion Resistance | Very high for most tactical use | Extremely high, for harsh abuse |

| Flexibility & Drape | Better, more flexible | Stiffer, bulkier |

| Comfort for Wearables | Excellent for vests & carriers | Good, but heavier and stiffer |

| Typical Applications | Plate carriers, tactical packs, pouches | Heavy-duty packs, belts, gear bags |

| Best Selling Point | Lighter with strong durability | Maximum toughness & rugged image |

10. 500D Cordura vs 1000D Cordura Fabric – TDS Comparison

| Item | Unit | Test Method | 500D Cordura Fabric (Typical) | 1000D Cordura Fabric (Typical) | Remark |

|---|---|---|---|---|---|

| Fiber Content | – | – | 100% Nylon 6 / 6,6 | 100% Nylon 6 / 6,6 | As per our fabric |

| Yarn Denier | D | – | 500D × 500D | 1000D × 1000D | As per our fabric |

| Weave Construction | – | – | Plain / Ripstop / Basket | Plain / Ripstop / Basket | As per our fabric |

| Finished Width | cm / inch | – | 147–150 cm (58–59″) | 147–150 cm (58–59″) | As per our fabric |

| Finished Weight | g/m² (gsm) | ISO 3801 / ASTM D3776 | 200–260 gsm | 320–370 gsm | As per our fabric |

| Thickness | mm | ASTM D1777 | 0.40 mm | 0.50-0.60 mm | As per our fabric |

| Coating Type | – | – | 1–2 Layer PU Coating / TPU Lamination | 1–2 Layer PU Coating / TPU Lamination | As per our fabric |

| Coating Weight | g/m² (gsm) | – | 10–50 gsm | 15–70 gsm | As per our fabric |

| Finish | – | – | DWR, optional IRR / FR | DWR, optional IRR / FR | As per our fabric |

| Color Range | – | – | Black, Coyote, Ranger Green, Wolf Grey, etc. | Black, Coyote, Ranger Green, Wolf Grey, etc. | Custom colors available |

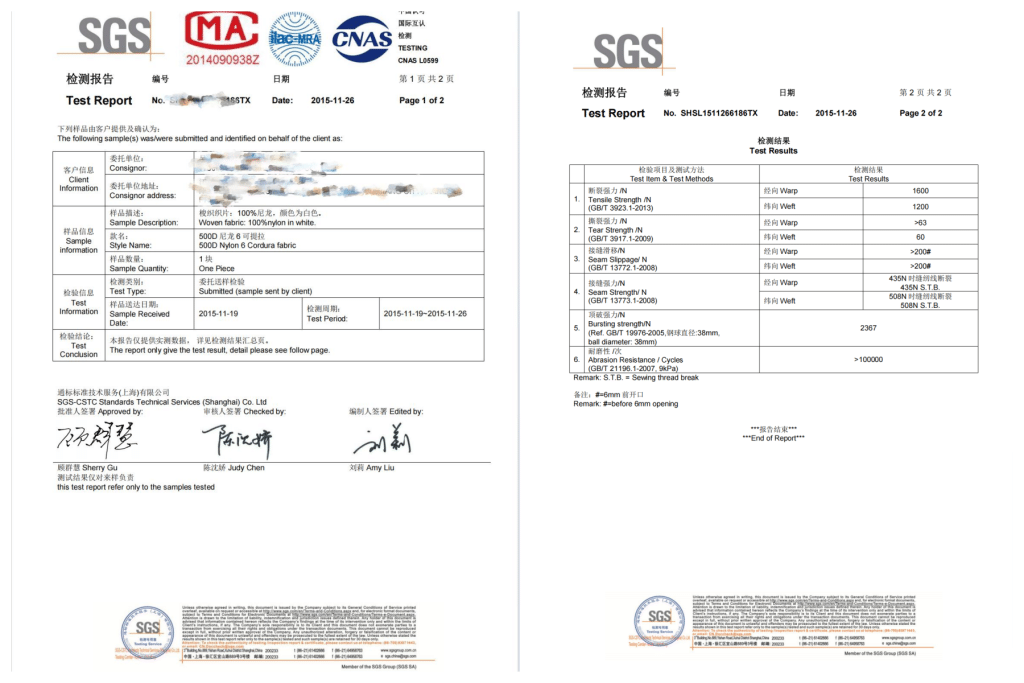

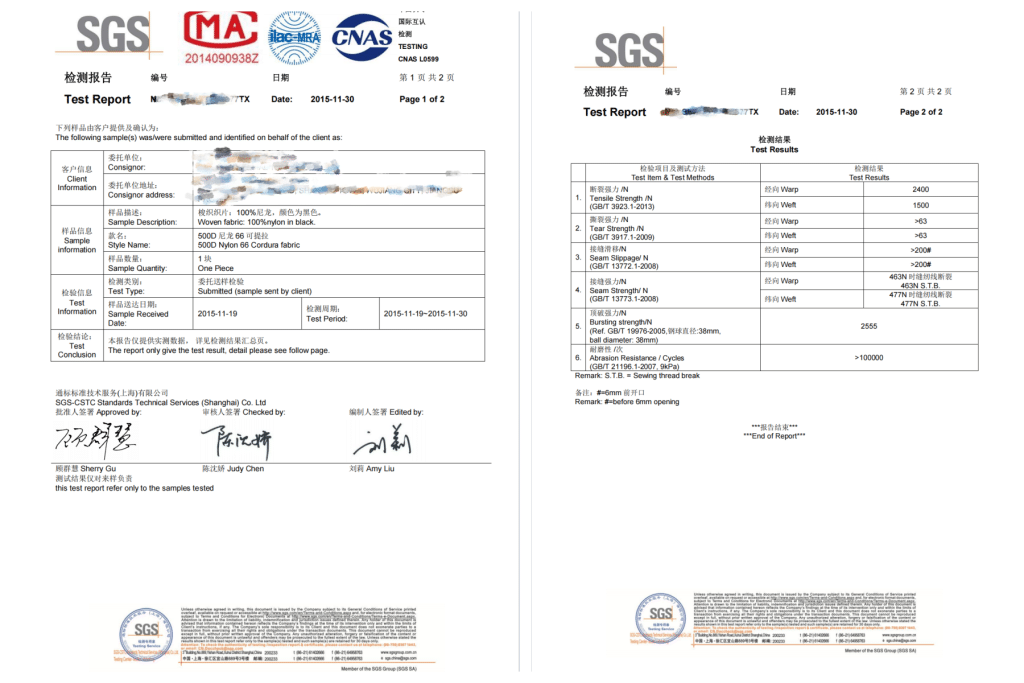

| Tensile Strength – Warp | N / 5cm | ISO 13934-1 / ASTM D5034 | 1600 N (Nylon 6), 2400N(Nylon 66) | 2400 N (Nylon 6), 3100N(Nylon 66) | As per our fabric lab data |

| Tensile Strength – Weft | N / 5cm | ISO 13934-1 / ASTM D5034 | 1200 N (Nylon 6), 1500N(Nylon 66) | 1800 N (Nylon 6), 2500N(Nylon 66) | As per our fabric lab data |

| Tear Strength – Warp | N | ISO 13937-2 / ASTM D1424 | ≥ 64 N (Nylon6, Nylon 66) | ≥ 128 N (Nylon6, Nylon 66) | As per our fabric lab data |

| Tear Strength – Weft | N | ISO 13937-2 / ASTM D1424 | ≥ 64 N (Nylon6, Nylon 66) | ≥ 128N (Nylon6, Nylon 66) | As per our fabric lab data |

| Abrasion Resistance | cycles | ISO 12947 / ASTM D3884 | ≥ 100,000 (Nylon6, Nylon 66) | ≥ 100,000 (Nylon6, Nylon 66) | As per our fabric lab data |

| Water Repellency (Spray Test) | Grade | AATCC 22 / ISO 4920 | Grade 90 | Grade 90 | Depends on DWR performance |

| Hydrostatic Head | mm H₂O | AATCC 127 / ISO 811 | ≥ 800–2000 mm (single PU), ≥ 20,000 mm (TPU) | ≥ 800–2000 mm (single PU), ≥ 20,000 mm (TPU) | As per our fabric lab data |

| Color Fastness to Washing | Grade | ISO 105-C06 | Grade 3-4 | Grade 3-4 | As per our fabric lab data |

| Color Fastness to Rubbing | Grade | ISO 105-X12 | Dry 4–5, Wet 3–4 (example) | Dry 4–5, Wet 3–4 (example) | |

| Color Fastness to Light | Grade | ISO 105-B02 | Grade 4 | Grade 4 | Tactical use: 4–5 recommended |

| Dimensional Stability | % | ISO 5077 | Warp/Weft ≤ ±3% (example after washing) | Warp/Weft ≤ ±3% (example after washing) | As per our fabric lab data |

| Operating Temperature Range | °C | – | –20°C to +50°C (example) | –20°C to +50°C (example) | As per our fabric lab data |

| Typical Applications | – | – | Tactical backpacks, plate carriers, pouches, EDC bags | Heavy-duty packs, range bags, belts, drag bags, cases | Short, application-oriented |

| MOQ | m / color | – | 800 m / color (need surchage if less than 800m) | 500 m / color (need surchage if less than 500m) | As per our fabric production data |

| Lead Time | days | – | e.g. 15–20 days after color approval | e.g. 15–20 days after color approval | As per our fabric production data |

| Compliance / Standards | – | – | RoHS, REACH, optional IRR / FR to specified standards | RoHS, REACH, optional IRR / FR to specified standards |

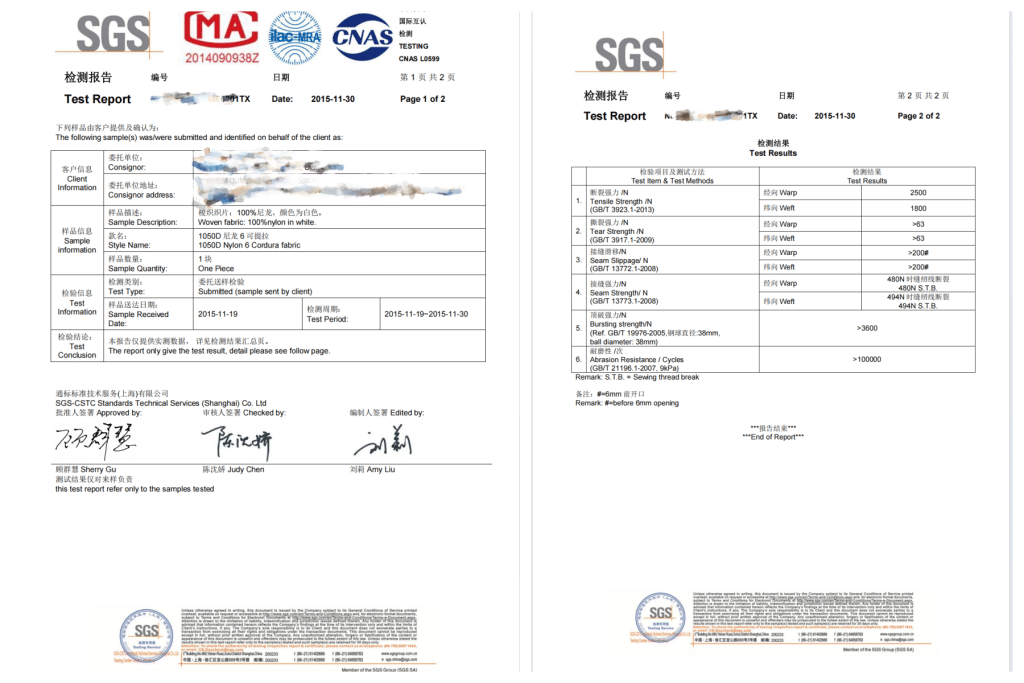

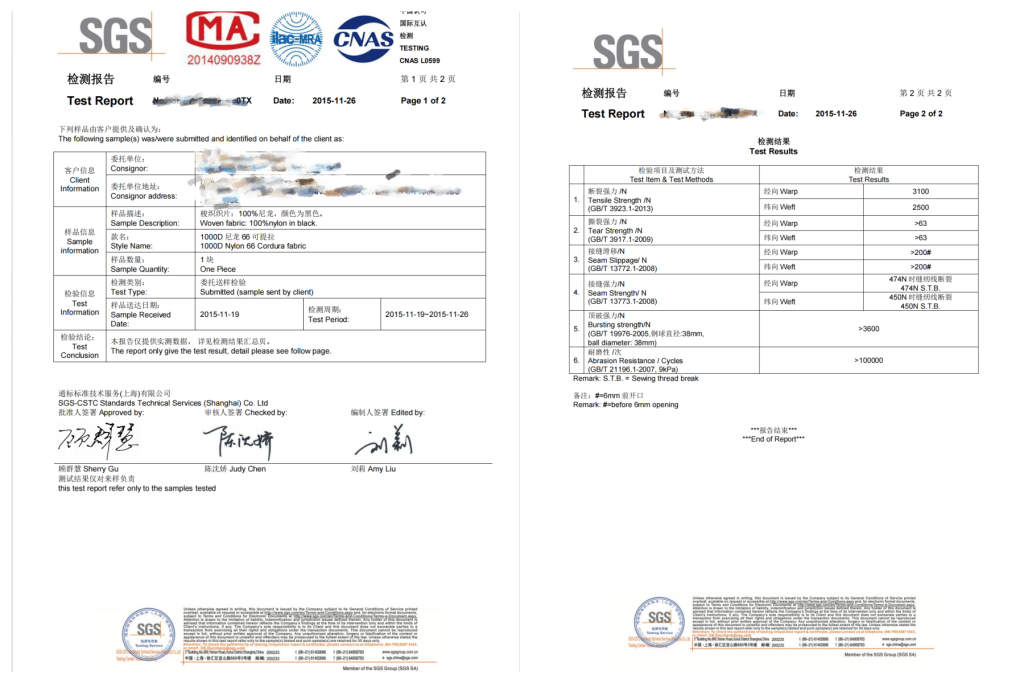

11. SGS CNAS-Certified Test Report for 500D and 1000D Cordura Fabrics

12. Conclusion: 500D vs 1000D – Which Denier Is Better?

There is no absolute “winner,” but there is a better match for each application:

- For plate carriers and most modern tactical backpacks:

- 500D Cordura is usually the optimal choice – lighter, comfortable, and still very durable.

- For extreme heavy-duty packs, range bags, and gear that faces constant abuse:

- 1000D Cordura may be preferred – maximum abrasion resistance and a very rugged feel.

13. FAQ: 500D Cordura vs 1000D Cordura for Tactical Gear

Q1: Is 1000D Cordura always stronger than 500D?

Not always in every parameter, but generally, 1000D shows higher abrasion, tear, and tensile strength due to heavier yarn and fabric mass. However, 500D Cordura is already very strong for most tactical uses, especially when combined with good sewing and construction.

Q2: Does 500D Cordura tear easily compared with 1000D?

No. 500D Cordura is still a high-performance tactical fabric. In normal use (duty, patrol, training), 500D will not “tear easily.” Many professional plate carriers and backpacks from top brands use 500D without durability complaints.

Q3: Which denier is better for a military plate carrier?

For most modern designs, 500D Cordura is better because it reduces weight and improves comfort while providing sufficient durability. 1000D can be used as reinforcement on high-stress zones if needed.

Q4: Which denier is more comfortable to wear?

500D Cordura is more comfortable because it is lighter, more flexible, and less stiff. This makes a big difference for chest rigs, plate carriers, and shoulder straps.

Q5: How do coatings affect the choice between 500D and 1000D?

Coatings (PU, PVC, TPU) and finishes (DWR, IRR, FR) affect water resistance, handle, and performance. Both 500D and 1000D can be made waterproof or IRR-compliant. When comparing options, always look at the complete TDS, not only the denier number.

Q6: For a new tactical backpack brand, what do you recommend?

A very common and successful formula is:

- Use 500D Cordura as the main body fabric.

- Add reinforced panels or double layers in high-wear areas (bottom, corners, strap anchors).

- This gives your customers a lightweight but tough backpack that feels modern and premium.

Q7: Can I mix 500D and 1000D Cordura in one product?

Yes. This is actually a popular design strategy. For example, use 500D for the main panels (comfort, weight saving) and 1000D for bottom panels, drag handles, and high-wear zones. You can highlight this in your product descriptions as a “hybrid construction”.

Q8: Do you provide customized finishes like IRR or FR on 500D and 1000D Cordura?

Yes, we can supply both 500D and 1000D Cordura-type fabrics with IRR, FR, waterproof, and other functional finishes according to your specification and standard. Please contact us with your requirement details.

14. Request a Quote and Technical Datasheet

If you are sourcing 500D or 1000D Cordura-type tactical fabrics for backpacks, plate carriers or military gear and need real lab data instead of theory, feel free to contact us. We can provide:

Latest FOB price based on your denier, finish and order quantity

Full TDS with tensile, tear, abrasion and hydrostatic head data

SGS / CNAS test reports (upon request)

Swatches and small yardage for your sampling and field testing

Contact Us for a Detailed Offer:

Company: Lean Textile Co., Ltd.

Website: cordurafabric.com

Email: [email protected]

WhatsApp / WeChat: 008615051486055

Send us your target denier (500D or 1000D), color, coating/finish (PU, TPU, IRR, FR, etc.) and end use (backpack / plate carrier / pouch), and we will recommend a suitable construction and quote you accordingly.